Testing Items for Stretch Film

Wrapping film, also known as stretch film, is a new type of industrial packaging film products. It is characterized by light, soft and thin, good tensile properties, elongation properties and self-adhesive properties. Its application in transportation packaging is a packaging method that improves packaging efficiency and saves costs. In order to ensure the production quality of packaging stretch film, manufacturers need to produce according to certain standards.

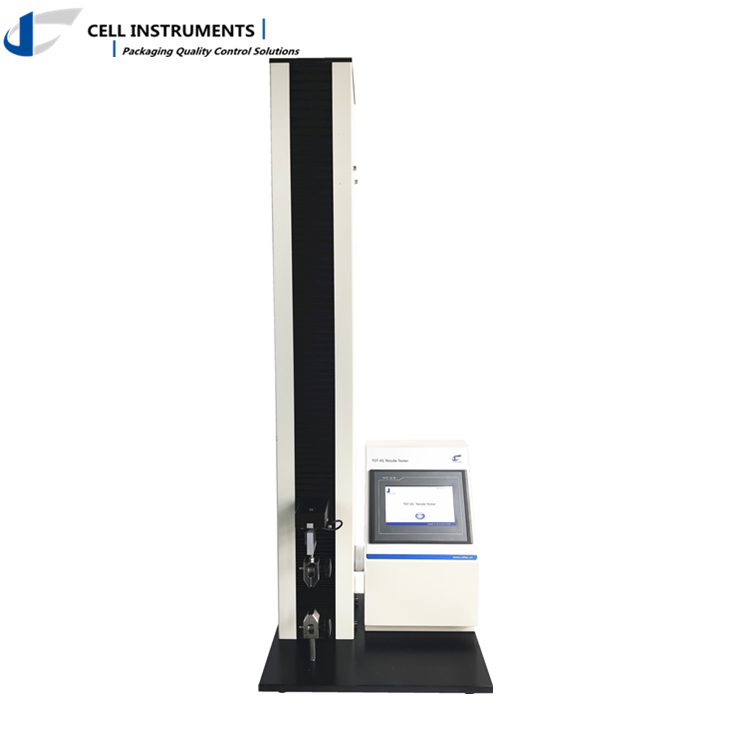

CELL INSTRUMENTS presents a range of testers designed for stretch film testing, including thickness measurement, tensile force and elongation at break (ASTM D882).

Thickness measurement

Cut the entire sample of 100mm along the length direction, measure 20 points after standing for 30min, the reading is accurate to 0.001mm, and take the arithmetic mean value.

Tensile force and elongation at break, according to ASTM D882

Samples are cut to a width of 15mm. The sample should be cut after unwinding roll for 1m, and cut evenly at approximately equal intervals along the length or width of the sample. Set the TST-01 tensile testing machine gauge length to 50mm, and the test speed is 250mm/min±25mm/min. There are two sets of vertical and horizontal sets, each set of samples shall not be less than 5, and the arithmetic mean value shall be taken, accurate to 0.1N.

Peel Cling Force test according to ASTM D5458

The Peel Cling Force test, conducted in accordance with ASTM D5458, assesses the adhesion properties of stretch film. For accurate and reliable results, it is crucial to follow the specified procedures outlined in the standard.

- Sampling: Initiate the test after unrolling the sample by 1m. Divide the samples into two groups: 500mm×125mm (vertical×horizontal) and 180mm×25mm (vertical×horizontal).

- Clamping: Clamp the samples securely, adhering to the method stipulated in the ASTM D5458 standard.

- Test Procedure: Pull the clamp at a speed of 125mm/min±12.5mm/min until the two samples separate. Record the maximum force value during the separation process.

- Measurement Accuracy: Ensure that the readings are accurate to 0.1N, maintaining precision in the test results.

Stretch Film Peel Cling Tester SPC-01

Protrusion Puncture Resistance test according to ASTM D5748

The ASTM D5748 protrusion puncture resistance test is realized on CELTEC TST-01 tensile tester, with the special probe and sample clamps with certain test area.

Fix the sample in sample clamps required. Start the tester and test the puncture needle at a speed of 250mm/min±12.5mm/min, and the test will stop when the puncture probe passes through the film completely. If the film is broken at other positions, the sample shall be discarded. Record the rupture force (N) and elongation (mm) of the sample when it ruptures.