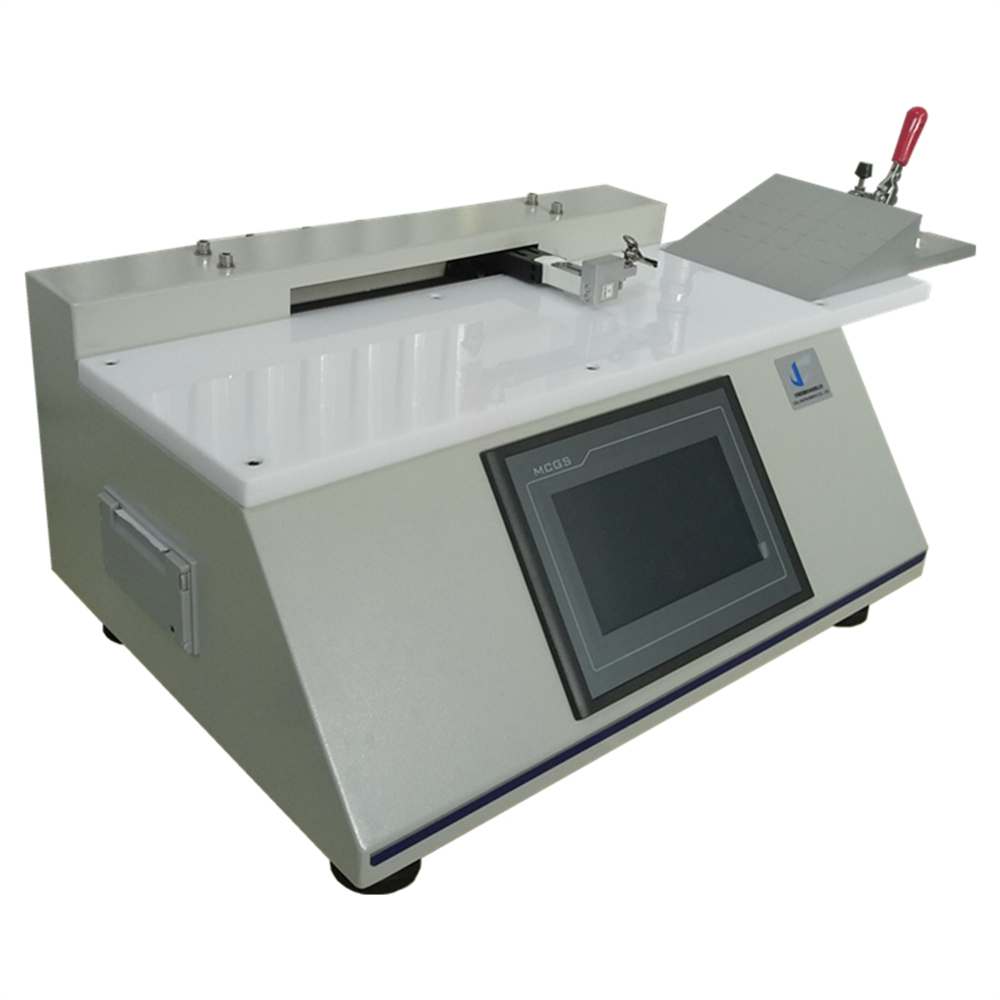

SPC-01 Stretch Film Peel Cling Tester

Stretch film, also known as cling wrap, plays a crucial role in securely bundling and protecting goods during transit and storage. Assessing the peel cling quality of stretch film is essential for evaluating its adhesion strength and overall performance.

Introduction of Peel Cling Tester

ASTM D5458 Peel Cling Tester measures cling between two layers of film and help to determine the property of stretch wrap material ability to adhere to it. In the realm of packaging materials, ensuring product safety and stability is paramount across diverse industries. Among these materials, stretch film, also known as cling wrap, plays a crucial role in securely bundling and protecting goods during transit and storage. Assessing the peel cling quality of stretch film is essential for evaluating its adhesion strength and overall performance.

Why Peel Cling Testing is Important?

Peel cling testing is crucial for stretch film because it assesses the film’s ability to adhere to itself and maintain the integrity of the wrapped goods.

Load Stability

The primary function of stretch film is to stabilize loads during transportation and storage. If the film doesn’t cling properly to itself, it can lead to load shifting, which may cause damage to the goods or even accidents during transit.

Product Protection

Proper cling ensures that the wrapped goods are securely held together, protecting them from dust, moisture, and other external factors that could potentially damage or contaminate them.

Efficient Handling

A stretch film with good cling properties makes it easier to handle and transport palletized loads, reducing the risk of slippage or separation during handling.

Cost Savings

Effective cling properties mean that less film is needed to wrap a load securely. This not only reduces material costs but also minimizes the environmental impact associated with excess packaging.

Customer Satisfaction

Ensuring that products arrive at their destination intact and undamaged is essential for customer satisfaction. Proper cling testing helps manufacturers maintain the quality of their products throughout the supply chain.

Application of Peel Cling Testing in Materials Testing

The Peel Cling Tester serves as a vital tool in evaluating the adhesion strength between two layers of stretch film. By providing precise measurements, this tester significantly contributes to enhancing product quality and safety across diverse sectors, including packaging, food, medical, and more.

Compliance with Standards

- The ASTM D5458 Standard Test Method for Stretch Wrap Peel Cling offers a standardized approach to quantify adhesion strength between film layers. This method aids in determining the superior adhesion layer, whether external or internal.

Technical Features of Peel Cling Tester

- User-Friendly Interface: A 7-inch TFT touch screen ensures easy operation and interaction.

- Reliable Performance: Internal PLC control unit guarantees consistent and dependable performance.

- Precision and Accuracy: Utilizes a precision ball screw mechanism for accurate speed and displacement measurements.

- Adjustable Test Speed: Allows flexibility in test parameters to suit specific testing requirements.

- Minimized Interference: Different load cell connections eliminate interference typically caused by friction and gravity, ensuring accurate results.

- Enhanced Functionality: Equipped with a limiting device and automatic return function for added convenience.

- Real-time Data Display: Provides real-time display of test curves and records peak values for analysis.

- Versatile Usage: Supports elongation rates of 50%, 100%, and 200%, catering to a wide range of testing needs.

- Documentation: Includes an embedded microprinter for convenient documentation of test results.

- Optional Features: Offers the option of adding a coefficient of friction function for comprehensive testing capabilities.

The peel cling quality of stretch film is pivotal for ensuring the integrity and stability of packaged goods during transportation and storage. The Peel Cling Tester stands as a reliable solution for accurately assessing cling adhesion strength, thereby contributing to enhanced product quality and safety across diverse industries.

How to test Peel Cling Force of Stretch Film?

FAQs

- Which industries benefit most from peel cling testing?

Peel cling testing is invaluable across industries such as packaging, food, medical, and pharmaceuticals, where securing goods during transit is critical. - Can the Peel Cling Tester accommodate customized testing requirements?

Yes, the Peel Cling Tester offers adjustable parameters, making it suitable for various testing needs, including customized automation. - Does peel cling testing comply with international standards?

Absolutely, peel cling testing, as conducted by the Peel Cling Tester, adheres to international standards such as ASTM D5458, ensuring accurate and reliable results. - How does peel cling testing contribute to quality control?

Peel cling testing serves as a vital quality control measure, ensuring the adherence and performance of stretch film in securing packaged goods effectively. - In what ways does the Peel Cling Tester aid in cost savings for businesses?

By accurately assessing cling adhesion strength, the Peel Cling Tester helps businesses optimize their packaging processes, minimizing material wastage and ensuring efficient resource utilization.

Related Testing Instruments

TST-01 Tensile Tester for Protrusion Puncture Resistance of Stretch Wrap Film