Overview

Leak and Seal Strength Test Method

This test method uses the pressure decay method. Internal pressurization of food saver bags or other sealed packages to determine the maximum strength they can withstand.

Leak and Seal Strength Test Process

First, fix the food saver bag on the fixture, pressurize the food saver bag to the set pressure, and cut off the air source. The pressure is then checked, and a drop in pressure indicates that the food saver bag has leaked. There are three methods A, B, and C in the standard for testing.

- Test Method A (Burst Test)—Place the package in the apparatus and increase the internal pressure until a failure occurs.

- Test Method B1 (Creep Test)—Place the package in the test apparatus, internally pressurize to the specified pressure, and maintain that pressure for a specified time.

- Test Method B2 (Creep to Failure)—Identical to Test Method B, except the pressure is held until the package fails.

This instrument will automatically output results to help tester determine the leak and seal strength of food saver bags.

Leak and Seal Strength Tester Technical Features

- PLC controlled unit (industrial level stable) and HMI touch screen operated.

- The tester is able to realize three test modes of burst, creep and creep to failure.

- Test result auto statistics and storage.

- Sensitivity and threshold personalized setting.

- Restraining plates can be equipped.

- Program customization available.

- Standard pressure up to 600KPa (87 psi) and can be modified to user requirement

- Compatible with other form of fixtures to facilitate tests to package form like open package (three-side-seal), closed package, doy pack, tube, sealed tray and cup, etc.

Leak and Seal Strength Tester Main Parameters

- Test Range 0~-600KPa

- Sample Width 300mm (standard)

- Inflating Head Φ4mm

- Compressed Air 0.4~0.7MPa ( Prepared by user)

- Power 110~220V 50/60Hz

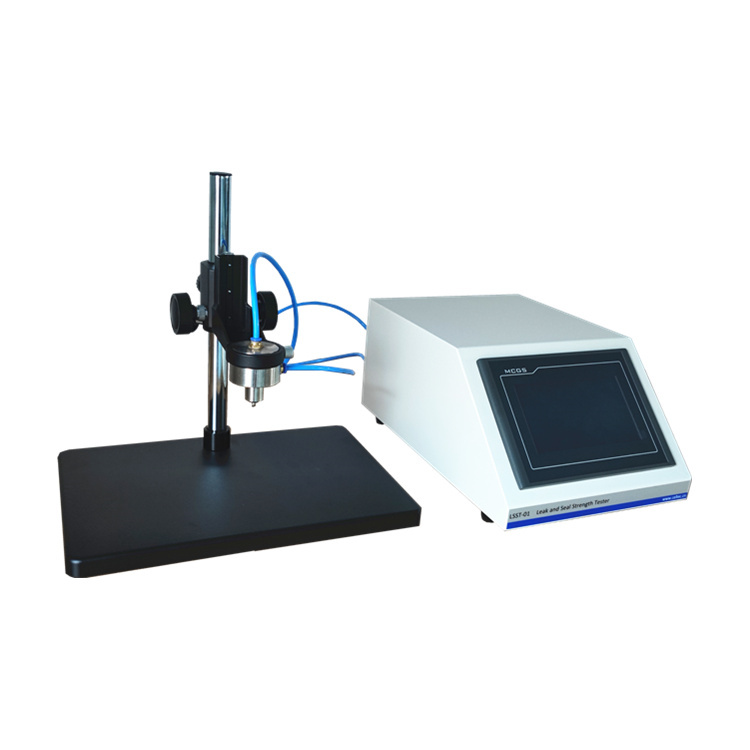

Leak and Seal Strength Tester Jigs Available

The LSST-01 Leak and Seal Strength Tester control unit can work with many standard and customized jigs for different applications and sample forms, such as sachet, bag, pouch, tube, bottle, doy pack, cell battery, jumbo bag, etc. Please contact our sales for a customized plan.

Standard

ASTM F2054 Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining Plates

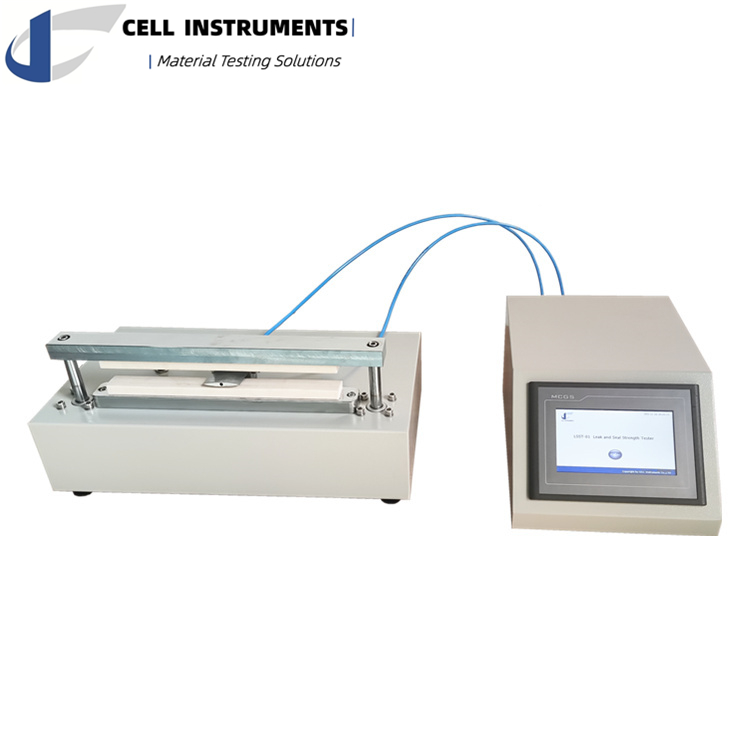

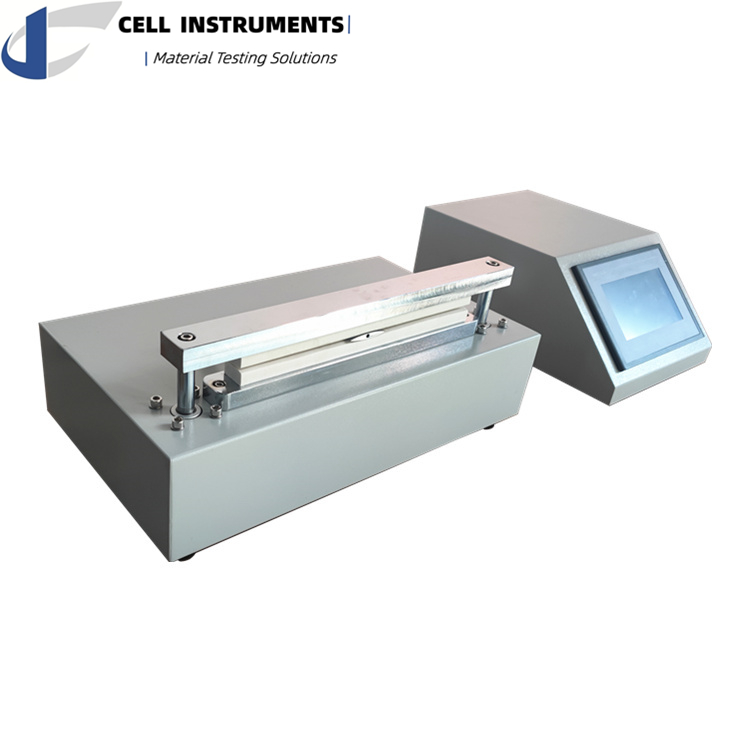

Leak and Seal Strength Testing Instruments Display

Related Products

Package Burst Testing Machine

Balloon Burst Tester

Leak and Seal Strength Tester

Related Article

Burst Test Packaging

Reference

ASTM F2054

ASTM F1140