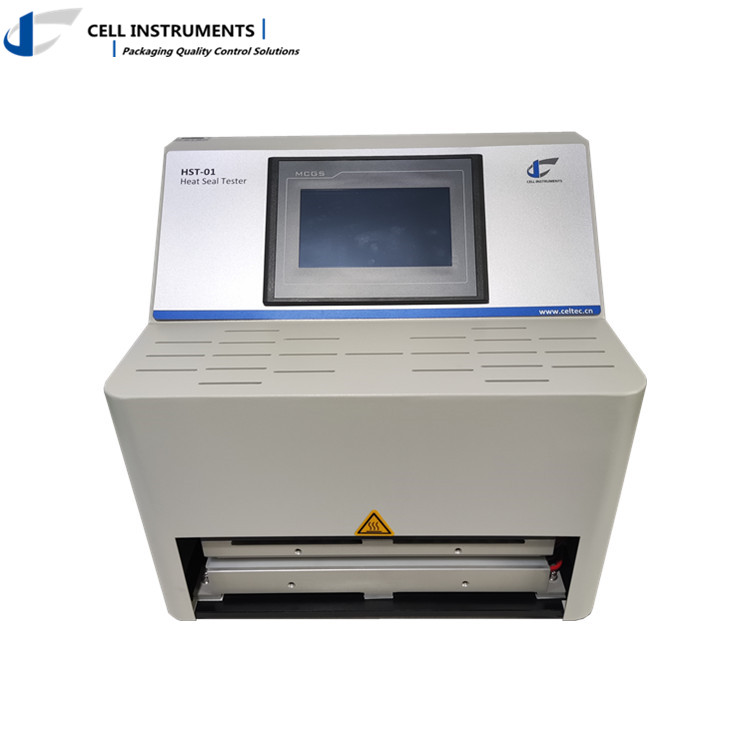

In a production line, our test accurately replicates the hot press sealing process. Our specially designed heat sealing head ensures compliance with industry regulations. By precisely adjusting the heat sealing pressure, time, and temperature, we can effectively control the quality of production and fine-tune the heat sealing data to achieve optimal results for various materials.

Why Choose our Heat Seal Simulation Test?

Controlled Parameters: Our test allows you to have full control over crucial parameters such as heat sealing pressure, time, and temperature. This ensures consistent and high-quality production.

Material Suitability: Our aim is to determine the most suitable heat sealing data for your specific material. By fine-tuning the variables, we ensure reliable seals.

Compliance and Quality Control: Our heat sealing head meets all industry regulations, guaranteeing the integrity of your production process and ensuring the highest standards of quality.

Improved Production Efficiency: By accurately replicating the hot press sealing process, we help streamline your operations, leading to enhanced productivity and reduced wastage.

Partner with us for Efficient Heat Sealing Solutions

As a leading provider of heat-sealing simulations, we understand the significance of maintaining an effective production line. By optimizing the heat-sealing process with our comprehensive test, you can achieve superior results in terms of quality, consistency, and efficiency. Contact us at qualitester@celtec.cn to learn more about our heat seal simulation services.