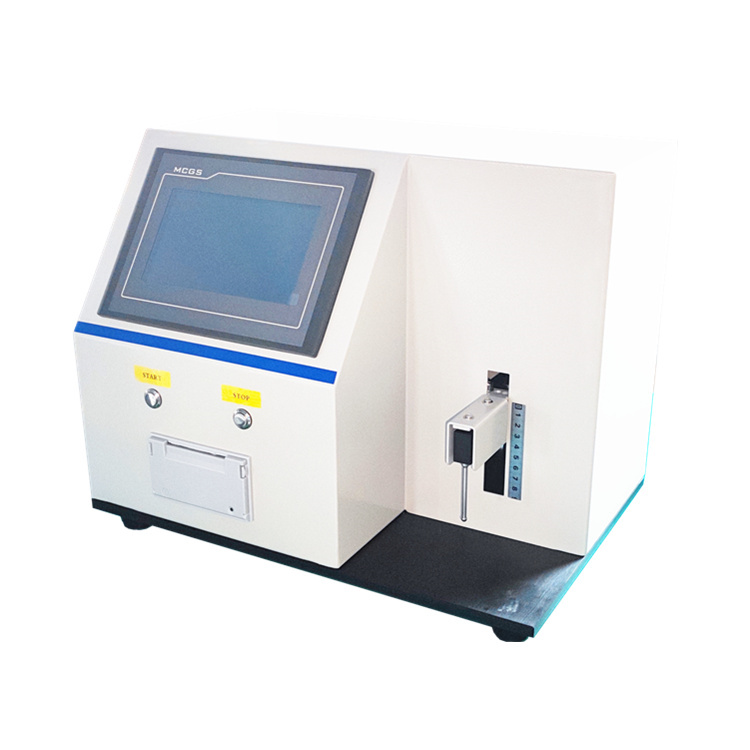

1. Introduction of the Gel Strength Tester

The gel strength tester is a highly specialized instrument designed to measure the firmness and cohesiveness of gels, including jelly, an essential parameter in various industries. It determines the mechanical strength of gel-like substances, ensuring consistency and quality in products. This instrument plays a critical role in sectors such as pharmaceuticals, food, cosmetics, and materials science, where precise control over the texture and stability of gels, including jelly, is crucial for product performance and consumer satisfaction.

2. Test Methods

1) Procedure Overview

Using the gel strength tester involves a straightforward process. First, the sample, such as jelly, is placed in the appropriate fixture. The instrument then applies a controlled force to the sample, measuring its response. The results are displayed in real-time on the touch screen.

2) Gel Strength Test Items

WEIGHT: To measure distance at a certain load

PEAK: To measure gel strength

DISTANCE: To measure load at a certain distance

3) Standard Test Protocols

The gel strength tester supports various industry-standard protocols, ensuring that the results are reliable and comparable across different laboratories and applications. These protocols define the specific conditions under which tests are performed, including temperature, humidity, and force application.

4) Sample Preparation

Proper sample preparation is crucial for accurate testing. Samples, including jelly, should be prepared according to the specific requirements of the test protocol, ensuring consistency in size, shape, and condition. This may involve conditioning the samples under controlled environmental conditions prior to testing.

5) Data Analysis

The data collected during testing is analyzed using integrated software. The software provides detailed reports on the gel’s strength, including parameters such as peak force, deformation, and recovery. This data is essential for understanding the material’s behavior under different conditions and making informed decisions about product formulation and quality control.

3. Gel Strength Tester Main Parameters

| Test Range | 0-50N (or as required) |

| Stroke | 1 10mm (without probe) |

| Test Speed | 1~100mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human-machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

4. Key Features

Our gel strength tester comes equipped with a range of advanced features to deliver accurate and reliable results:

- 7 Inch HMI Touch Screen: The user-friendly interface allows for easy operation and monitoring of tests. The large display provides clear visuals of the testing process and results.

- PLC Control Unit Inside: The programmable logic controller (PLC) ensures precise control over the testing parameters, enhancing the accuracy and repeatability of measurements.

- Precision Ball Lead Screw: This component guarantees smooth and consistent motion during testing, contributing to the overall precision of the instrument.

- Adjustable Test Speed: The ability to adjust the test speed provides flexibility to accommodate different types of gels, including jelly, and testing requirements.

- Multiple Fixtures Available: The tester can be equipped with various fixtures for different types of texture analysis, making it versatile for a wide range of applications.

- Travel Limit Protection: This safety feature prevents the instrument from exceeding its mechanical limits, protecting both the device and the sample.

- Automatic Returning and Loadcell Protection Cover: These features enhance the durability and safety of the instrument, ensuring it remains in optimal working condition.

- Multiple Test Items: The gel strength tester can measure various parameters, including weight, peak force, and distance, providing comprehensive data on the gel’s properties.

- Dot Matrix Type Microprinter Equipped: The built-in printer allows for immediate printing of test results, facilitating record-keeping and analysis.

5. Applications

1) Pharmaceutical Industry

In pharmaceuticals, the gel strength tester is used to evaluate the consistency and stability of gel-based medications, such as topical creams and gels. Ensuring the appropriate gel strength is vital for the efficacy and safety of these products.

2) Food Industry

The texture of food products, such as gelatin desserts, jelly, dairy products, and confectioneries, is critical for consumer acceptance. The gel strength tester helps manufacturers maintain the desired texture and quality, ensuring a pleasant eating experience.

3) Cosmetics and Personal Care

Cosmetic products like hair gels, lotions, and creams require specific textures for optimal application and performance. The gel strength tester ensures these products meet the required standards, enhancing user satisfaction.

4) Materials Science

In materials science, the tester is used to study the mechanical properties of various gel-like materials, contributing to the development of new materials with specific characteristics for industrial applications.

6. Customization and Automation

1) Custom Testing Solutions

We offer custom testing solutions to meet the unique needs of different industries. Whether it’s modifying the instrument to accommodate specific sample sizes or developing new test protocols, we work closely with our clients to provide tailored solutions.

2) Automation and Easy Operation

Our gel strength tester is designed for easy integration into automated testing workflows. The intuitive interface and advanced control systems minimize the need for manual intervention, increasing efficiency and reducing the risk of human error.

3) Upgrade and Support Services

We provide comprehensive support services, including instrument upgrades and maintenance. Our team of experts is available to assist with any technical issues, ensuring that your gel strength tester remains in optimal condition.

7. Benefits

1) Improved Product Quality

Accurate gel strength testing ensures that products, including jelly, meet the required standards for texture and stability, enhancing overall quality and performance.

2) Cost Efficiency

By providing reliable data on gel properties, our tester helps manufacturers optimize formulations and processes, reducing waste and lowering production costs.

3) Regulatory Compliance

The gel strength tester helps ensure that products comply with industry regulations and standards, avoiding potential legal and financial penalties.

8. FAQ

Q1. What is the purpose of a gel strength tester?

The gel strength tester measures the firmness and cohesiveness of gel-like substances, including jelly, which is crucial for ensuring consistency and quality in products across various industries.

Q2. How does the gel strength tester ensure accurate results?

Our tester features a precision ball lead screw, adjustable test speeds, and a PLC control unit to ensure precise control and accurate measurements.

Q3. What industries benefit from using a gel strength tester?

Industries such as pharmaceuticals, food, cosmetics, and materials science benefit from using the gel strength tester to ensure product quality and performance.

Q4. Can the gel strength tester be customized?

Yes, we offer custom testing solutions to meet specific industry needs, including modifications for different sample sizes and new test protocols.

Q5. How does the gel strength tester contribute to regulatory compliance?

By providing reliable data on gel properties, the tester helps ensure products meet industry standards and regulatory requirements, avoiding legal and financial penalties.