GFT Gelbo Flex Tester

The Gelbo Flex Tester is an essential instrument for evaluating the flex durability of flexible barrier materials, such as films, composites, and coating films. This device tests a material’s ability to withstand repetitive strain, which is crucial for preventing flex cracks and ensuring the integrity of packaging during distribution. Flex crack resistance is a vital property, as it minimizes the risk of package perforation, ensuring the contents remain intact throughout the packaging’s lifecycle.

The Gelbo Flex Tester is an essential instrument for evaluating the flex durability of flexible barrier materials, such as films, composites, and coating films. This device tests a material’s ability to withstand repetitive strain, which is crucial for preventing flex cracks and ensuring the integrity of packaging during distribution. Flex crack resistance is a vital property, as it minimizes the risk of package perforation, ensuring the contents remain intact throughout the packaging’s lifecycle.

ASTM F392 – Flex Durability of Flexible Barrier Materials

ASTM F392 is a standard specification that outlines the procedure for determining the flex durability of flexible barrier materials. This test method is specifically designed to evaluate the ability of materials like films and coatings to endure repeated bending, twisting, and flexing under stress, simulating real-world conditions during transport and handling. The test involves subjecting the sample to a series of flexing motions and determining the material’s ability to withstand these stresses without developing holes or cracks.

Standard Procedure for Conditioning Flexible Barrier Materials by Flex Durability Testing

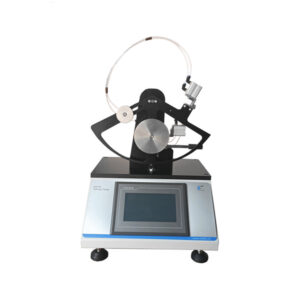

The Gelbo Flex Tester adheres to the testing procedures outlined in ASTM F392 for flex durability testing. The process involves mounting a sample measuring 200 mm by 280 mm onto the test mandrels. The sample is then subjected to both twisting and horizontal compression motions, designed to simulate the stresses packaging materials undergo during distribution. Specifically, the system initiates a twisting action that spans 440° within the first 90 mm of the stroke, followed by a horizontal compression of 65 mm.

The test is conducted at a speed of 45 cycles per minute with five pre-programmed test modes:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

This flexible testing process allows users to simulate various real-world stress scenarios, enabling precise assessments of flex crack resistance.

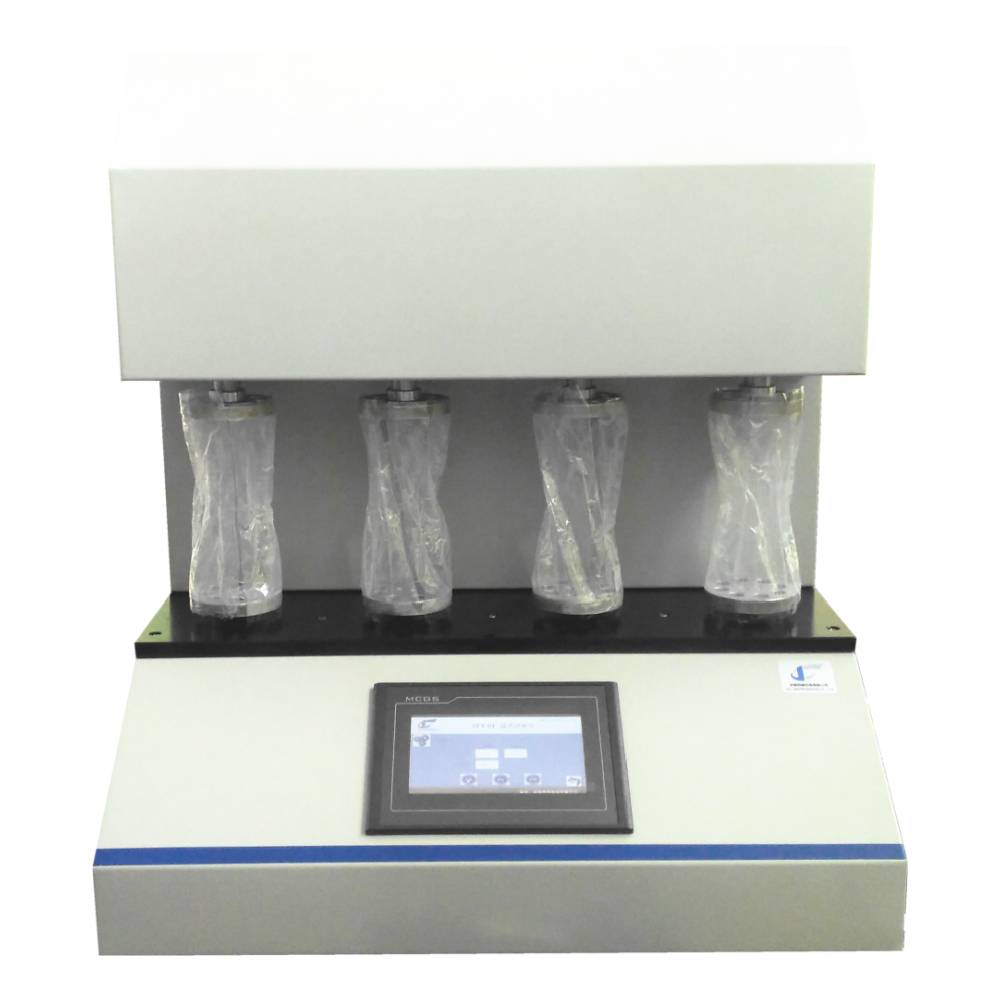

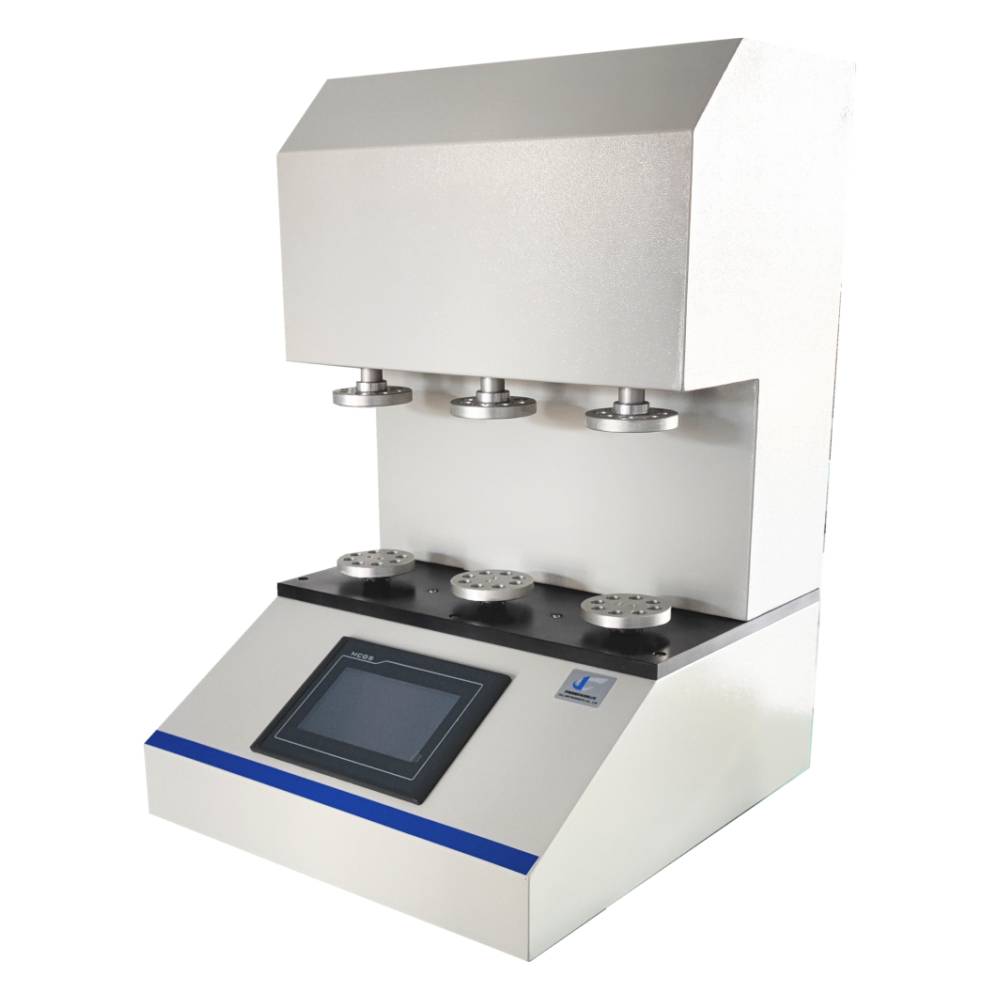

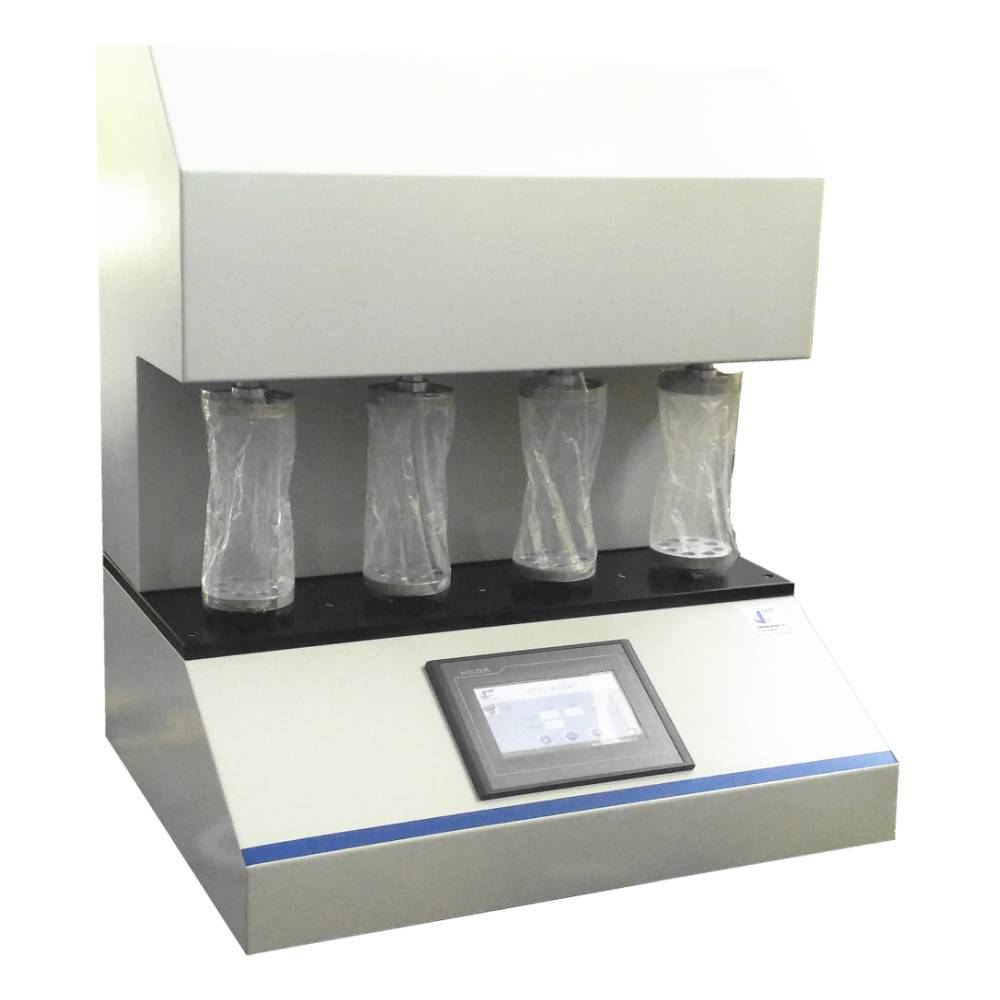

Gelbo Flex Tester Technical Features

- PLC Control: The Gelbo Flex Tester is equipped with PLC control for consistent, automated testing.

- Intuitive HMI Touch Screen Interface: The user-friendly interface makes it easy to monitor and control testing parameters.

- Five Standard Test Modes: The system offers flexibility with five pre-programmed modes, allowing users to select the ideal test conditions for their materials.

- Multiple Test Stations: The tester features 3 to 4 stations for concurrent testing, enhancing efficiency in testing large volumes of materials.

- Quick Mode Switching: Easily toggle between long and short stroke modes, providing customizable testing conditions.

- Microprinter for Data Output: The built-in microprinter allows for convenient printing of test results, ensuring data accuracy and traceability.

Application Areas for the Flex Durability Tester

The Flex Durability Tester is widely used in industries where packaging materials are subjected to repetitive stresses during transport and handling. These include:

- Packaging: Flexible films and laminates used for food, beverages, pharmaceuticals, and medical products.

- Medical Device Packaging: Ensuring the durability of packaging materials used for sterile medical devices.

- Pharmaceuticals: Testing barrier materials that protect sensitive drugs and medicines.

- Food and Beverage: Packaging materials designed to maintain the freshness and integrity of food products.

Main Parameters of the Gelbo Flex Tester

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Customization and Special Testing Requirements

Cell Instruments specializes in customizing testing equipment to meet specific material testing needs. The Gelbo Flex Tester can be tailored to suit a wide range of flexible material testing requirements, offering solutions for both standard and unique testing conditions. (Such as test procedures and sample fixtures)

FAQ

- What materials can be tested with the Gelbo Flex Tester?

The Gelbo Flex Tester is ideal for testing flexible barrier materials like films, composites, and coating films used in packaging, medical devices, food products, and more. - What is ASTM F392, and why is it important for testing?

ASTM F392 is a standard specification for testing the flex durability of flexible materials. It helps ensure that packaging materials can withstand repetitive strain during distribution, reducing the risk of perforation or failure. - Can the Gelbo Flex Tester be customized for specific testing needs?

Yes, Cell Instruments offers customization options to tailor the Gelbo Flex Tester to meet unique testing requirements across various industries. - How does the Gelbo Flex Tester simulate real-world stresses on packaging?

The tester uses a combination of twisting and horizontal compression motions to replicate the repetitive stresses that packaging materials experience during transport and handling.