Introduction to the Friction Coefficient Tester

The friction coefficient tester is a precision instrument designed to measure the static and kinetic coefficients of friction between two surfaces. These measurements are essential in evaluating the “slipperiness” or resistance of materials, particularly in industries where packaging, production efficiency, and material compatibility are critical. By accurately determining the coefficient of friction, manufacturers can optimize processes, improve product quality, and ensure smooth operation during production, storage, and transportation.

Importance of Coefficient of Friction Testing

The coefficient of friction plays a pivotal role in material behavior, affecting how products interact during production and use. A lower coefficient signifies better sliding performance, while a higher coefficient may indicate potential challenges such as sticking or jamming. Factors such as additives, coatings, treatments, and environmental conditions can all influence these frictional properties. Accurate testing helps manufacturers:

- Improve the handling and processing of materials.

- Prevent material defects caused by excessive friction.

- Optimize production line speeds and reduce downtime.

Standards Overview

To ensure uniformity and reliability, the friction coefficient tester complies with internationally recognized standards, including ASTM D1894 and ISO 8295.

ASTM D1894

- Overview: This standard specifies the method for determining the static and kinetic coefficients of friction of plastic film and sheeting.

- Test Method: Using the sled-and-plane method, the material’s resistance to sliding is measured under controlled conditions.

- Relevance: ASTM D1894 is widely adopted in the packaging industry to assess material compatibility and performance on machinery.

ISO 8295

- Overview: ISO 8295 provides guidelines for evaluating the coefficients of friction of plastic films and sheets.

- Test Method: Similar to ASTM D1894, it uses a sled to measure sliding resistance under standardized conditions.

- Relevance: This standard ensures global compliance for manufacturers working in international markets.

Comparison of ASTM D1894 and ISO 8295

While both standards focus on similar testing principles, they differ in certain parameters such as test speed and specific requirements. Complying with both ensures compatibility across diverse markets.

Applications of the Friction Coefficient Tester

The friction coefficient tester is versatile and applicable to a variety of materials, including:

- Packaging films: Assessing “slipperiness” for efficient machine operation.

- Paper and textiles: Evaluating frictional resistance for consistent product performance.

- Rubber and coatings: Measuring durability and usability in diverse conditions.

- Brake pads and tires: Ensuring safety through accurate friction assessments.

Working Principle and Formula

The tester employs the sled-and-plane method, where a weighted sled is dragged across a flat surface, and the force required is measured. The coefficient of friction is calculated using the formula:

μ=N/f

Where:

- μ: Coefficient of friction

- f: Force of friction

- N: Normal force

Static COF (μs): Measures the force needed to initiate movement.

Kinetic COF (μd): Measures the force required to maintain movement.

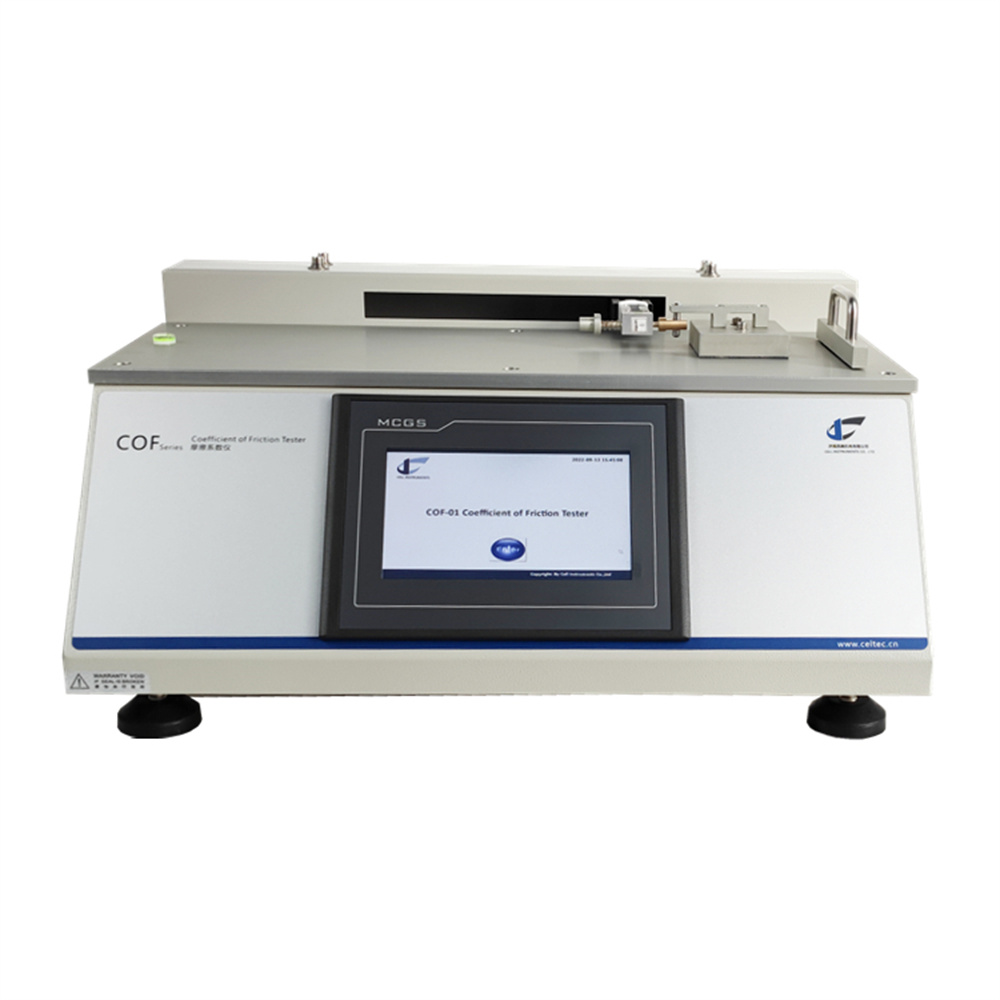

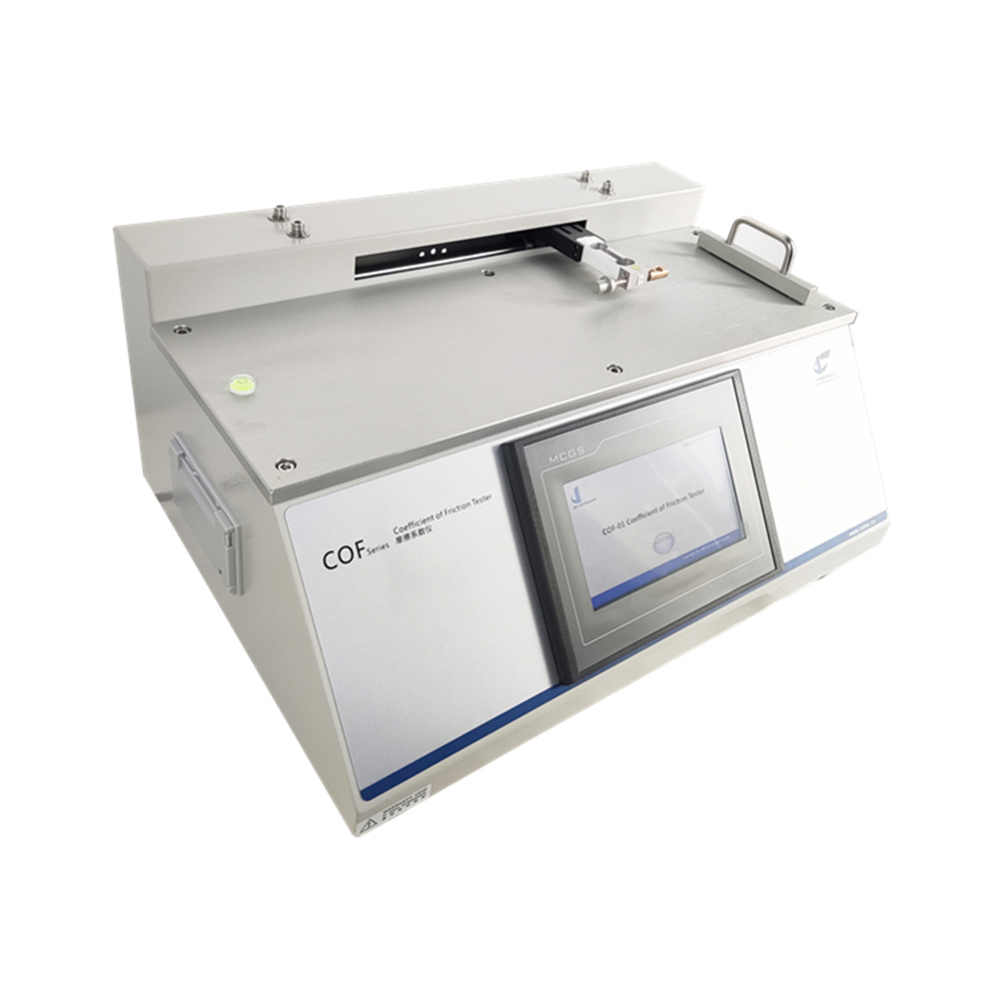

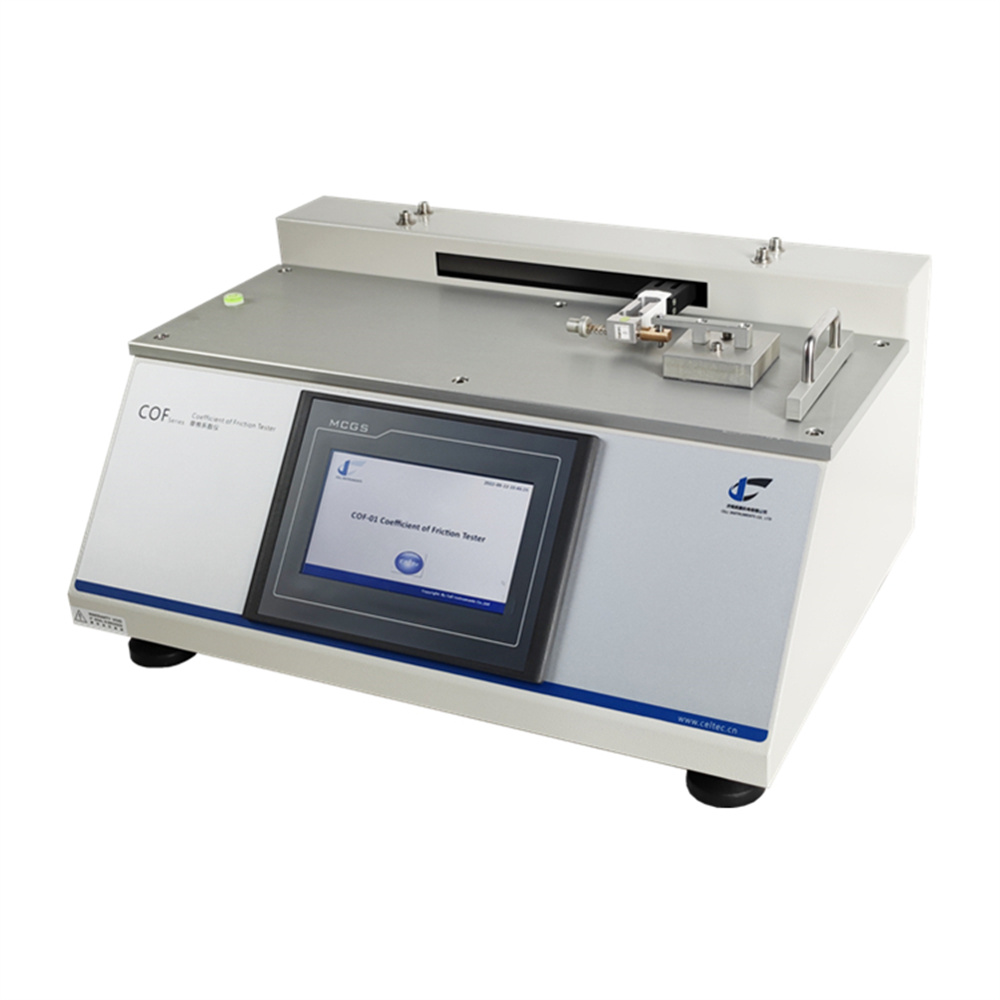

Features of the COF-01 Friction Coefficient Tester

The COF-01 Friction Coefficient Tester is engineered to deliver precise, reliable results with user-friendly operation:

- Advanced Control System: PLC-based control with an HMI touchscreen interface.

- High Precision Mechanics: Powered by a stepper motor and ball lead screw.

- Real-Time Analytics: Displays test curves and automatically records results.

- Standards Compliance: Fully adheres to ASTM D1894, ISO 8295, TAPPI T816, and GB 10006.

- Customizable Options: Load cell capacity, sled weight, and software can be tailored to meet specific needs.

- Robust Design: Durable aluminum test plane ensures longevity.

Technical Parameters

| Parameter | Specification |

|---|---|

| Load Cell | 5 N (customizable) |

| Accuracy | ±0.5% F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5 mm × 63.5 mm |

| Test Speed | 100 mm/min (ISO), 150 mm/min (ASTM) |

| Dimensions | 540 mm (L) × 380 mm (W) × 240 mm (H) |

| Weight | NW 21 kg |

| Power | 110–220 V, 50/60 Hz |

Benefits of the COF-01 Tester

- Enhances material quality by providing accurate friction data.

- Increases production efficiency by optimizing material compatibility.

- Meets international testing standards for global market acceptance.

Why Choose Cell Instruments?

Cell Instruments is a trusted name in material testing, offering innovative solutions tailored to industry needs. With expertise in customization and automation, we ensure that every product meets the highest standards of precision and usability.

FAQs

- What is the main purpose of a friction coefficient tester?

- It measures the static and kinetic coefficients of friction to ensure material compatibility and performance.

- What industries benefit from using the COF-01 Tester?

- Industries including packaging, textiles, coatings, adhesives, and automotive.

- What is the difference between static and kinetic COF?

- Static COF measures the force to start movement, while kinetic COF measures the force to maintain movement.

- What standards does the COF-01 comply with?

- ASTM D1894, ISO 8295, TAPPI T816, and GB 10006.

- Can the COF-01 Tester be customized?

- Yes, options such as sled weight, software integration, and display language are customizable.

Related Product