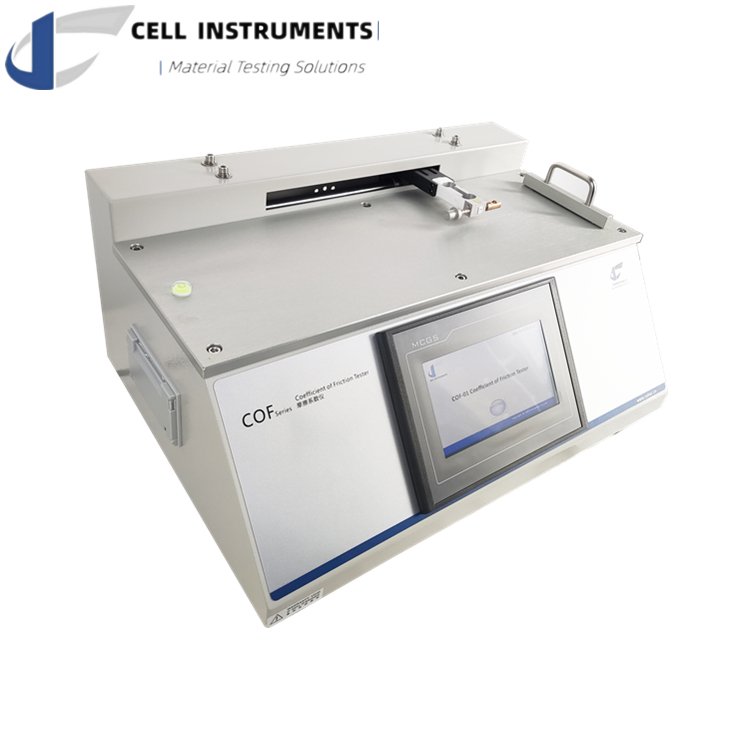

COF-01 Conveyor Belt Coefficient of Friction Detection Machine

The COF-01 Conveyor Belt Coefficient of Friction detection Machine plays a pivotal role in optimizing packaging processes across various industries. The COF-01 from Cell Instruments serves as a versatile solution, offering precise measurements and contributing to overall efficiency in diverse industries.

Coefficient of Friction Test Background

Coefficient of friction is the amount of friction existing between two surfaces. A low value of coefficient of friction means less force is required for sliding to occur. A higher value means more force is required.

Coefficient of friction (COF) will be different depending on the materials that are interacting with each other. Packaging film coefficient of friction (COF) refers to the level of ‘slip’ that the packaging material has when interacting with different parts of packaging machine, conveyor belt or materials.

Controlling coefficient of friction (COF) is important in optimizing performance and avoiding problems in forming, transporting, and storing of packages.

Coefficient of Friction Tester Application

Coefficient of Friction Tester COF-01 is for the measurement of static and kinetic coefficients of friction of plastic films, sheets, rubber, paper, paper board, woven and non-woven, fabrics, metal-plastic composite belts for communication cables, convey belts, wood, coatings, brake pads, windshield wipers, shoe materials and tires. By modification, it could be used for many other types of materials and test standards.

Coefficient of Friction Tester Technical Features

COF-01 Coefficient of friction tester has been helping flexible industry since its inception. The COF-01 has technical features that ensure accuracy and reliability in testing. With PLC control and HMI touch screen, it guarantees stability and a prolonged service life. The stepper motor and precision ball lead screw driving mechanism, along with real-time test curve display, contribute to its efficiency.

- It uses PLC control units and HMI touch screen.

- Stepper motor and precision ball lead screw driving mechanism.

- Real time test curve display, max, min and average test result auto recording.

- Both static and kinetic coefficient of friction and measured.

- Comply with multiple test standards.

- Dot matrix type micro printer embedded.

- All aluminum test plane.

- RS232 output and professional software (optional)

- Support local language display

Coefficient of Friction Tester Main Parameters and Specifications

- Load Cell 5 N (or as required)

- Accuracy 0.5 F.S.

- Sled 200 g (or as required)

- Sled Size 63.5mm*63.5mm (or as required)

- Test Speed 100mm/min (ISO), 150mm/min (ASTM)

- Dimensions 540mm(L)*380mm(W)*240mm(H)

- Weight NW 21kg

- Power 110-~220V 50/60Hz

Coefficient of Friction Tester Major Standards

The tester complies with multiple test standards, including:

- ASTM D1894

- ISO 8295

- TAPPI T816

- GB 10006

Controlling coefficient of friction (COF) is paramount for optimizing packaging performance and preventing issues during forming, transportation, and storage. The COF-01 Conveyor Belt Coefficient of Friction Tester stands as an indispensable tool for businesses seeking to enhance their packaging processes. By understanding and controlling coefficient of friction (COF), industries can optimize their performance and minimize potential challenges.