Use

Test Method

Test Method A (Burst Test)—Place the package in the apparatus and increase the internal pressure until a failure occurs.

Test Method B1 (Creep Test)—Place the package in the test apparatus, internally pressurize to the specified pressure, and maintain that pressure for a specified time.

Test Method B2 (Creep to Failure)—Identical to Test Method B, except the pressure is held until the package fails.

Technical Features

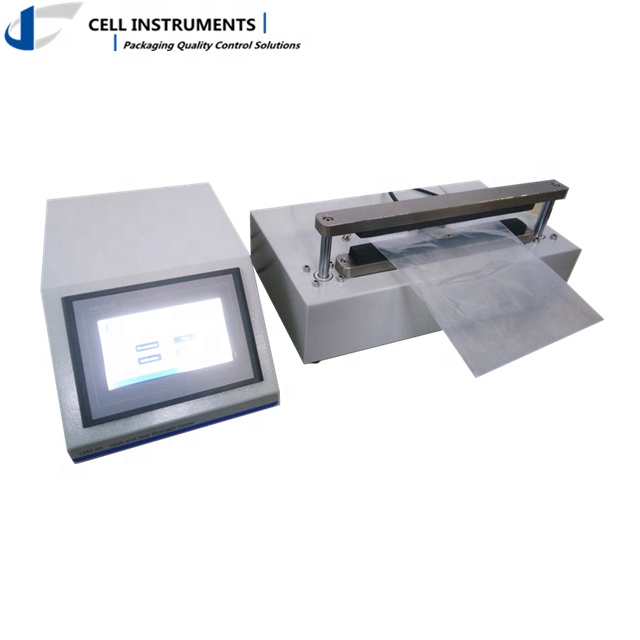

☛PLC controlled unit (industrial level stable) and HMI touch screen operated.

☛The tester is able to realize three test modes of burst, creep and creep to failure.

☛Test result auto statistics and storage.

☛Sensitivity and threshold personalized setting.

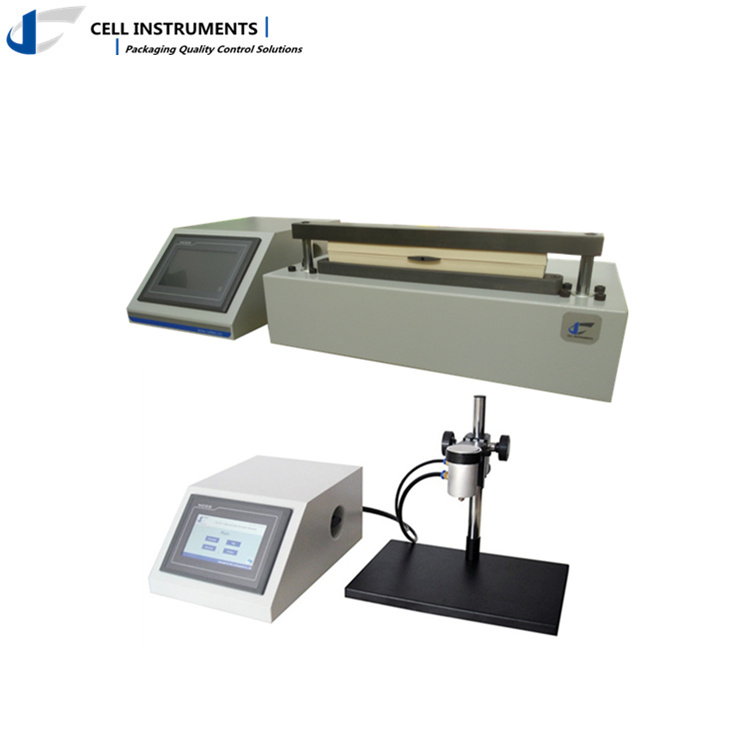

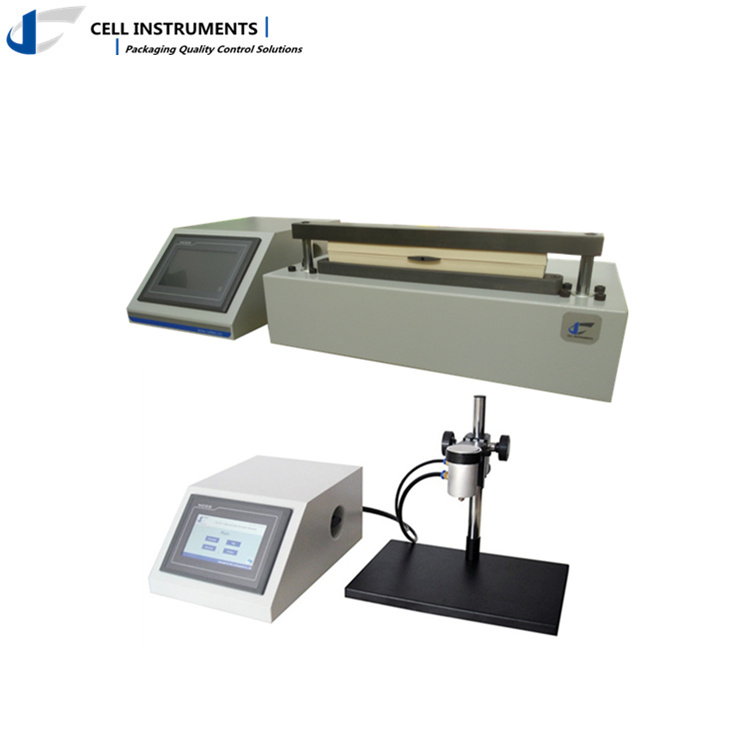

☛Restraining plates can be equipped.

☛Program customization available.

☛Standard pressure up to 600KPa (87 psi) and can be modified to user requirement

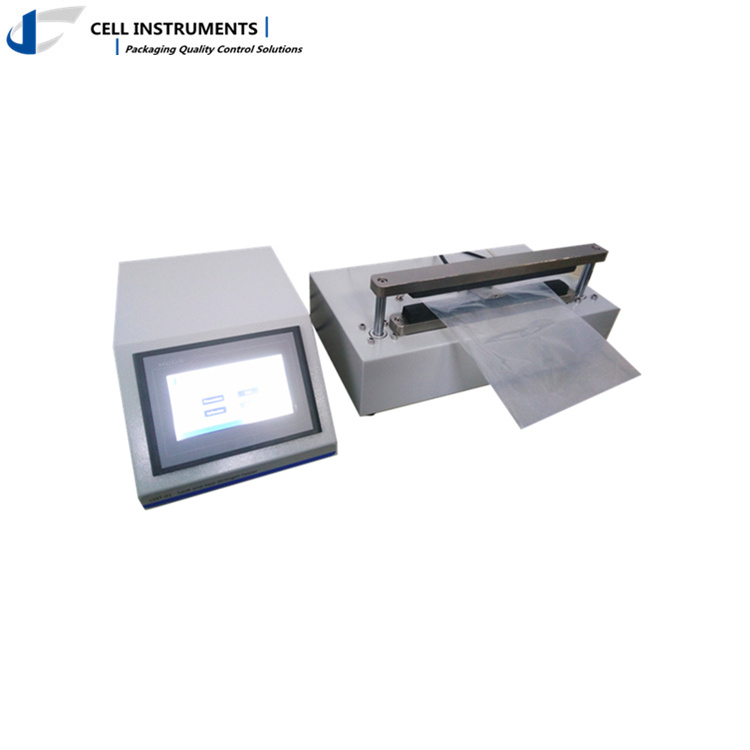

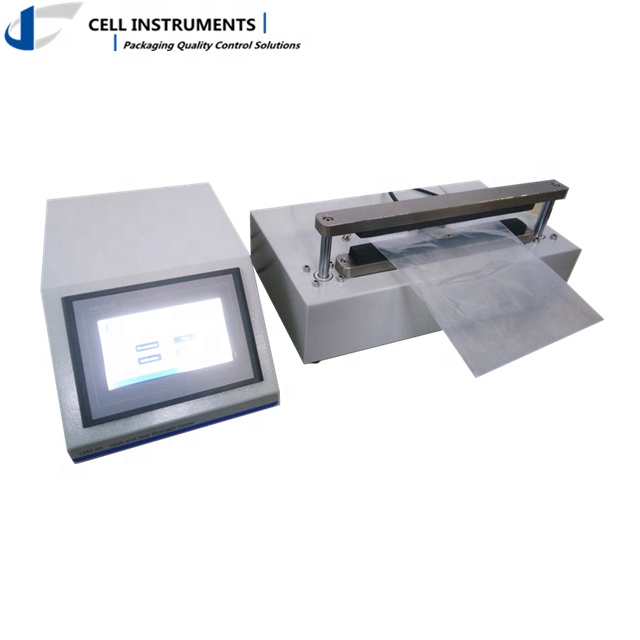

☛Compatible with other form of fixtures to facilitate tests to package form like open package (three-side-seal), closed package, doy pack, tube, sealed tray and cup, etc.

Main Parameters

Test Range 0~-600KPa

Sample Width 300mm (standard)

Inflating Head Φ4mm

Compressed Air 0.4~0.7MPa ( Prepared by user)

Power 110~220V 50/60Hz

Jigs Available

The LSST-01 control unit can work with many standard and customize jigs for different applications and sample forms, such as sachet, bag, pouch, tube, bottle, doy pack, cell battery, jumbo bag, etc. Please contact our sales for a customized plan.

Standard

ASTM F2054 Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining Plates