Food packaging testing is important because it ensures that the materials used to package food are safe and suitable for their intended use. It also helps to ensure that the packaging materials do not contaminate the food, and that the food is protected from spoilage, contamination, and other hazards. Testing also helps to ensure that the packaging materials meet regulatory requirements and industry standards.

1.Food Package Testing Instruments for Impact Resistance Property

Testing the impact resistance of packaging materials can ensure effective protection of the contents. The impact resistance test can be divided into falling dart impact and pendulum impact.

FBT-01 Falling Ball Impact Tester

PIT-01 Film Impact Tester

2. Food Package Testing Instruments for Tearing Property

The product tears and breaks due to external force during storage and transportation. Sufficient tear resistance can reduce tearing and prevent leakage.

SLD-01 Tear Tester: complies with the Elmendorf method and is suitable for tear strength testing of films, laminated films, foils, paper and cardboard.

SLD-01 Tear Tester

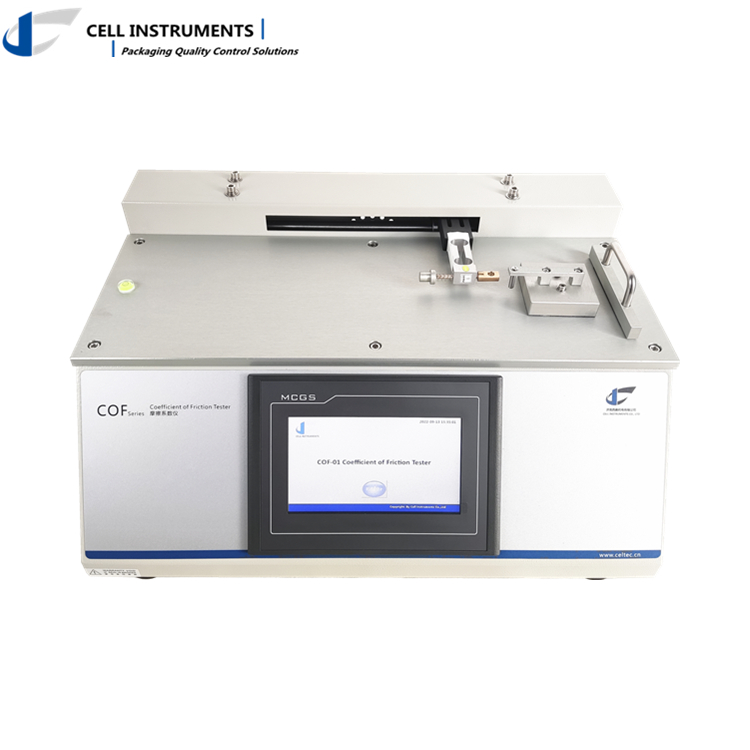

3.Food Package Testing Instruments for Coefficient of Friction

Proper smoothness on both sides of the material can ensure good opening and smooth transportation and packaging on the assembly line.

COF-01 Coefficient of Friction Testers

COF-03 Inclined Plane Coefficient of Friction Tester

FPT-01 Friction and Peel Tester

4.Food Package Testing Instruments for Thickness

Thickness is the basic indicator for inspecting thin films. Uneven thickness affects tensile strength and barrier properties as well as further processing.

FTT-01 Thickness Tester

5.Food Package Testing Instruments for Printing Testing

This is to test the bonding strength of the ink layer of printed materials.