In the manufacturing of magnetic materials like electrical steel and amorphous strips, lamination factor plays a vital role in determining material quality. It affects the efficiency of motors, transformers, and other electromagnetic components. To assess this critical parameter, a lamination factor tester offers a precise, standardized method for measurement.

What Is Lamination Factor and Why Is It Important?

Lamination factor—also known as lamination stacking factor or space factor—is the ratio of the true metal volume to the apparent volume of a stacked set of metal strips. It quantifies how efficiently material is packed, considering the effects of surface roughness, coatings, and voids between layers.

In magnetic core applications, a high lamination factor minimizes energy losses and improves performance. Therefore, it is a critical parameter for quality assurance in the electrical, electronics, and motor industries.

Working Principle of a Lamination Factor Tester

A lamination factor tester determines the stacking efficiency by comparing the measured stack volume under pressure with the calculated solid volume based on the material’s mass and density.

Key test steps include:

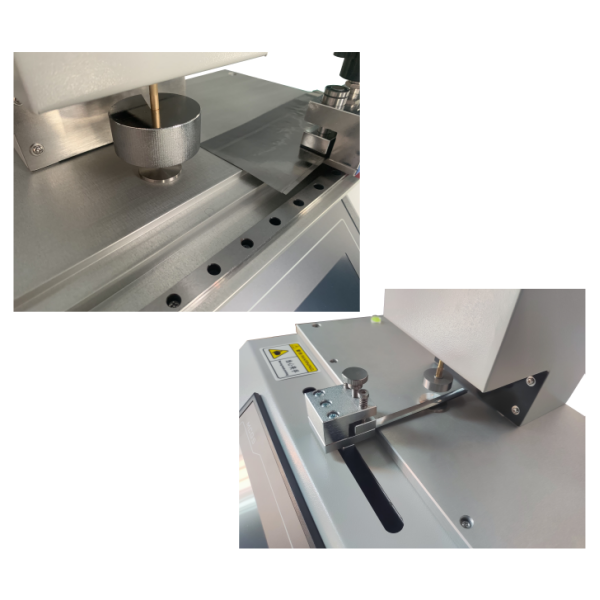

- Cutting the magnetic material into uniform strips

- Stacking the strips in alignment

- Applying a standard pressure using the tester

- Measuring the compressed stack height

- Calculating the lamination factor using the formula:

S = m / (l · w · δ · h · k)

Where:

S = lamination factor (%)

m = mass of the stack

l, w = length and width

δ = material density

h = compressed height

k = unit conversion constant

The process requires high measurement precision to reflect small variations that could impact the stacking factor.

Standards Referenced in Lamination Factor Testing

To ensure global compliance and consistency, lamination factor testers must align with recognized standards. The most referenced include:

ASTM A719 – Magnetic Materials

Defines the standard method for measuring lamination factor in ferromagnetic materials. It emphasizes uniform pressure (typically 50 psi), precise stack height measurement, and correct mass-to-volume calculations.

ASTM A900 – Amorphous Magnetic Strips

Specially developed for thin, amorphous magnetic strips, this method requires alignment fixtures, micrometer measurements, and careful stacking due to the sensitivity of the material.

ASTM A683 – Semiprocessed Electrical Steel

Refers to the use of ASTM A719 as the designated test method. It emphasizes that a higher lamination factor indicates better quality, particularly in smoother and thicker materials.

IEC 60404-13 – Global Electrical Steel Standard

Provides international guidelines for stacking factor measurement across all electrical steel types. It requires accurate weighing, dimensional precision, and pressure application of 1.00 ± 0.05 N/mm².

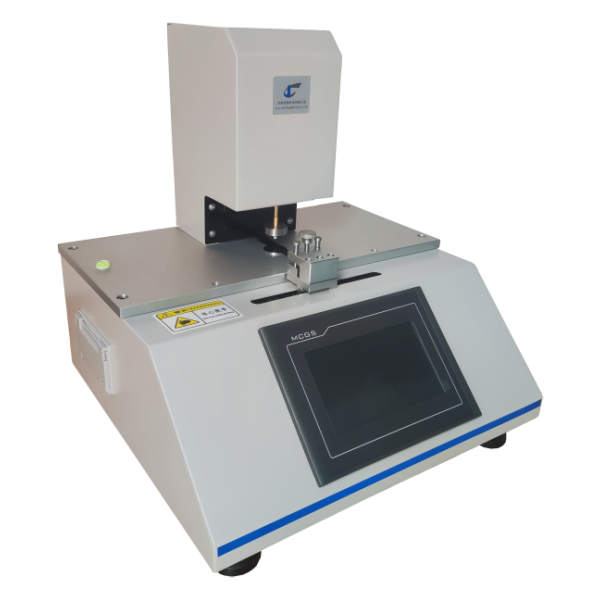

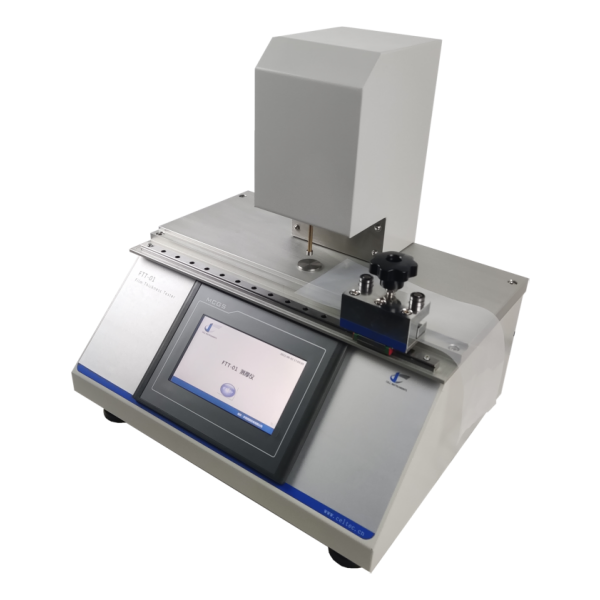

Introducing the FTT-02 Lamination Factor Tester by Cell Instruments

For laboratories and production environments requiring reliable lamination factor testing, the FTT-02 Lamination Factor Tester itibaren Hücre Enstrümanları is a professional-grade solution.

Key Features:

- Test Range: 0–2 mm (customizable)

- Resolution: 0.1 μm for precise stack height measurements

- Test Pressure: 50 ± 0.5 kPa (standard, per ASTM A719)

- Indenter Size: Ø14–17 mm (adjustable to suit sample types)

- Compact Design: 461 × 334 × 357 mm, suitable for various lab setups

The FTT-02 is engineered for easy specimen alignment, automated height measurement, and stable pressure control, ensuring highly accurate lamination factor results.

Applicable Materials:

- Nonoriented and grain-oriented electrical steels

- Amorphous and nanocrystalline magnetic strips

- Thin coated electrical materials used in motor cores

By following ASTM and IEC testing procedures, the FTT-02 minimizes human error and enhances result repeatability.

Applications and Benefits of Lamination Factor Testing

The lamination factor test is essential in:

- Transformer and motor core production

- Magnetic material quality control

- R&D labs evaluating new alloys and coatings

- Conformity assessment for international shipment or certification

Key Benefits:

- Detects voids, roughness, and coating effects

- Ensures material quality and consistency

- Helps optimize lamination design and process parameters

- Supports compliance with ASTM A719, A900, and IEC 60404-13

Understanding and controlling the lamination factor of magnetic materials is crucial for energy-efficient product design and manufacturing. Accurate measurement requires precision equipment that complies with international standards like ASTM A719, ASTM A900, ASTM A683, and IEC 60404-13.

Bu FTT-02 Lamination Factor Tester by Hücre Enstrümanları offers industry-leading accuracy, user-friendly operation, and full compliance with global testing protocols. Whether you’re a materials engineer, a QA manager, or a manufacturer of magnetic components, this instrument ensures your lamination factor results are reliable, traceable, and professional.

FAQs

1. What is the purpose of a lamination factor tester?

It determines how efficiently magnetic strips are stacked by calculating the ratio of solid metal volume to the total volume, indicating material quality.

2. Which standards should be followed for lamination factor testing?

Relevant standards include ASTM A719, ASTM A900, ASTM A683, and IEC 60404-13, depending on the material type.

3. Can the FTT-02 be used for thin amorphous strips?

Yes, the FTT-02 supports various materials including thin amorphous magnetic strips, thanks to its adjustable pressure and high-resolution measurement.

4. What factors affect the lamination factor?

Surface coatings, material roughness, oxide layers, and air gaps between strips can lower the lamination factor.

5. How does lamination factor impact electrical performance?

A higher lamination factor means better magnetic coupling and less energy loss, improving the efficiency of motors, transformers, and inductors.