Packaging integrity is a critical factor in the medical, pharmaceutical, and food industries, where compromised seals can result in contamination, product degradation, or regulatory noncompliance. Among various testing methods, the bubble leak test stands out as a widely adopted, cost-effective, and visual technique to assess packaging seal performance. Whether used for sterile barrier systems or vacuum-sealed pouches, this test provides fast and reliable results for detecting even minor leaks.

Bubble Immersion Leak Test and ASTM F2096: Industry Standard for Medical Packaging

O bubble immersion leak test, formalized under Norma ASTM F2096, offers a standardized approach to detecting gross leaks in flexible medical and pharmaceutical packages. This method involves immersing the test specimen in water and applying vacuum pressure to create a differential between the inside and outside of the package. If a defect exists, bubbles will visibly form, indicating the leak’s location.

Key aspects of ASTM F2096 include:

Applicable to porous and non-porous flexible packaging.

Defines test parameters such as immersion time, vacuum level, and observation method.

Ensures reproducibility across laboratories and packaging formats.

A well-executed bubble immersion leak test not only identifies leak locations but also confirms overall package integrity under simulated storage or shipping conditions.

How the Bubble Leak Test Works

Preparação

The test sample (such as a medical pouch or sachet) is partially inflated or sealed, depending on the packaging type.Immersion

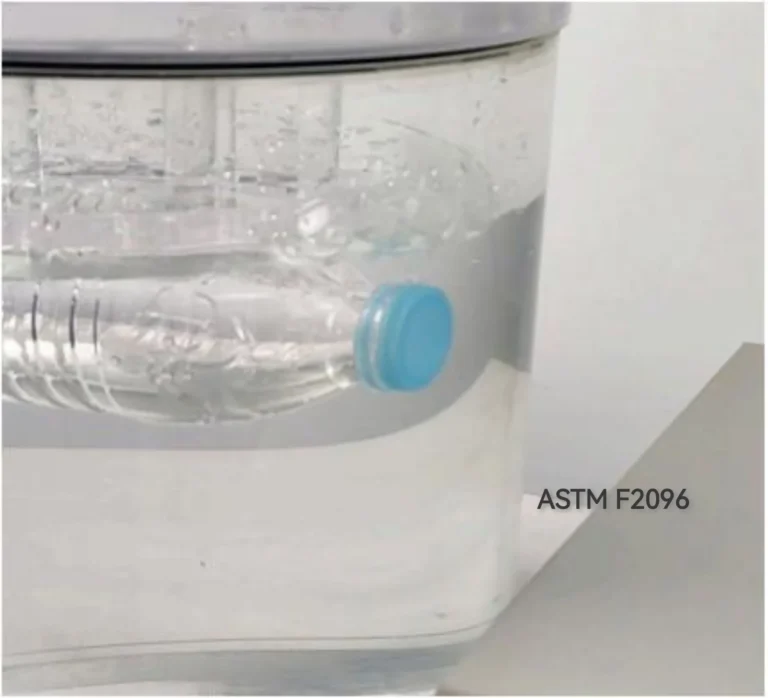

The package is submerged into a transparent acrylic chamber filled with water.Aplicação de vácuo

UM vacuum system—such as a Venturi vacuum system—is used to apply controlled negative pressure (often up to -90 kPa) to the chamber. This creates a pressure differential.Observation

If the package has a leak, the pressure difference forces trapped air out through the defect, resulting in visible bubbles rising from the package. This is a visual pass/fail test.

This process is typically non-destructive if no leak is present and can be done manually or semi-automatically using a reliable medical package bubble leak tester.

Applications in Quality Control and Regulatory Compliance

O bubble leak test is frequently used for:

Embalagem para dispositivos médicos: Blister packs, syringe pouches, and sterile bags.

Pharmaceutical Packaging: Capsule strips, sachets, and vials.

Embalagem de alimentos: Vacuum-sealed or MAP films used in meat, cheese, and produce.

In regulated environments, such as hospitals or pharmaceutical plants, adhering to Norma ASTM F2096 and similar standards ensures that testing methods are acceptable for audits, FDA inspections, and global certifications.

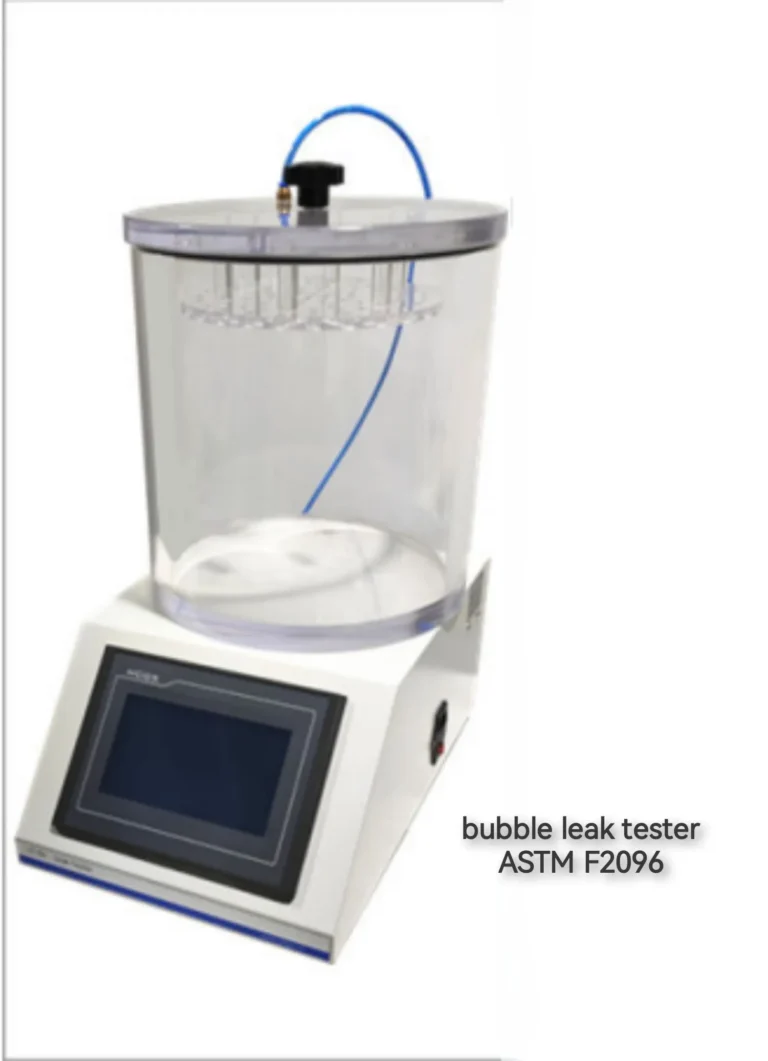

Recommended Solution: Cell Instruments Bubble Leak Tester

For precise and repeatable results, Cell Instruments offers a robust solution: the Bubble Leak Tester. Designed with a transparent acrylic chamber, Venturi vacuum system, and no electrical requirement, it ensures reliable testing even in field conditions. The tester is customizable to accommodate various package sizes and operates effectively up to -90 kPa, making it ideal for both lab and production environments.

Why Choose the Bubble Leak Test for Medical Packaging?

Alta Sensibilidade: Detects even small leaks by visualizing micro-bubbles.

Simple Operation: Minimal training required, especially with transparent chambers and intuitive controls.

No Calibration Needed: Reduces downtime and operational complexity.

Compliance Friendly: Aligned with ASTM F2096, ensuring global recognition.

Custo-efetivo: No complex instrumentation or consumables involved.

By incorporating this test into your quality assurance workflow, you can significantly reduce risk, improve packaging standards, and maintain product sterility throughout the supply chain.

Conclusion: Strengthening Seal Integrity with the Bubble Leak Test

O bubble leak test is a simple yet powerful tool that empowers manufacturers and quality control professionals to uphold packaging integrity across industries. Backed by standards like Norma ASTM F2096, it plays a vital role in ensuring the safety, performance, and compliance of medical and pharmaceutical packaging. For companies looking to implement or upgrade this testing method, Cell Instruments provides dependable, easy-to-use equipment tailored to your needs.