Background

A heat sealer is a machine that utilizes heat to securely seal various products, packaging materials, and thermoplastic substances, including plastic bags. This sealing process involves applying heat and pressure to effectively join thermoplastic materials together. Heat sealers are extensively used in different industries to create and seal a wide range of items, including plastic bags and various packaging solutions.

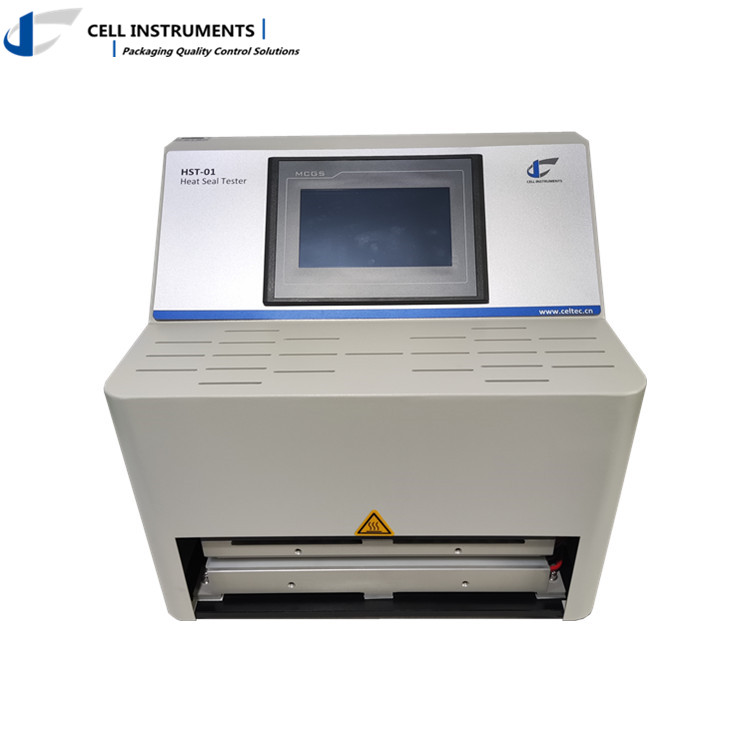

In laboratory testing, a valuable tool called a Heat Seal Tester is used. This compact and versatile heat sealer is specifically designed to assess the heat sealability of different surfaces, sealant layers, films, laminates, composites, polymers, and more. By subjecting these materials to controlled heat and pressure, the Heat Seal Tester enables researchers and professionals to accurately determine the effectiveness of their sealing processes.

To achieve optimal seal quality, three crucial parameters must be considered: time, temperature, and pressure. The successful interaction and optimization of these parameters are essential for creating reliable and durable seals. The heat seal tester acts as a simulation tool, allowing users to precisely set and control these parameters, replicating real-world seal conditions and ensuring consistent and reproducible results.

The strength of seals in flexible packaging, such as plastic bags, is highly important as it indicates functional performance and ease of opening. Strong and secure seals not only ensure the protection and preservation of the packaged contents but also contribute to customer satisfaction by allowing easy access to the product. By using heat seal testers, manufacturers and researchers can evaluate and improve the seal strength of flexible packaging, leading to enhanced product quality and user experience.

Standard

ASTM F2029-16(2021) :Standard Practices for Making Laboratory Heat Seals for Determination of Heat Sealability of Flexible Barrier Materials as Measured by Seal Strength

Technical feature

When it comes to evaluating the heat sealability of materials such as films, laminates, composites, polymers, foil bags, and plastic bags, ensuring the stability and precision of a heat seal tester is absolutely crucial. That’s where our HST-01 heat seal tester truly stands out, thanks to its state-of-the-art design that guarantees exceptional sealing results. Let’s delve into its key features that make it reliable, accurate, and user-friendly for optimal sealing performance, including plastic bags:

- The unit is equipped with a PLC-controlled system, ensuring industrial-level stability, and operated through an HMI touch screen interface.

- Both the upper and lower parts of the tester are made of aluminum and heated to minimize heat loss during sealing, guaranteeing consistent temperature distribution.

- A first-class P.I.D. (proportional integral derivative) temperature controller enables precise temperature control and efficient heating.

- Accurate timing combined with a proximity sensor allows for simultaneous seal initiation with jaw movement.

- The three-way guided sealing bar ensures uniform sealing pressure.

- User protection features include an anti-scald front cover and manual/foot switches to initiate tests, ensuring safety.

- The seal jaw can be customized in terms of dimensions, shape, and sealing surface/patterns.

- The tester includes an RS 232 COM Port and optional computer software for data analysis and configuration.

In summary, the HST-01 heat seal tester is a reliable and efficient solution for evaluating the heat sealability of materials such as films, laminates, composites, polymers, foil bags, and plastic bags. Its advanced features, user-friendly interface, robust construction, precise temperature control, adjustable pressure settings, and data logging capabilities make it an excellent choice for achieving optimal sealing results in diverse packaging applications, including the production of plastic bags.

Key Data

Sealing Temp. Room Temp. ~ 300℃

Deviation ±0.2℃

Sealing Time 0.1s~9999s

Sealing Pressure 0.15 MPa ~ 0.7 MPa

Seal Jaws 330 mm × 10 mm (Customization Available)

Gas Pressure 0.7 MPa

Port Size Ф6 mm PU Hose

Dimensions 455mm (L) ×320mm (W) ×440mm (H)

Power AC 220V 50Hz(Customization Available)