Introduction to Film Pendulum Impact Tester

O film pendulum impact tester is a precision instrument used to evaluate the impact resistance of plastic films, foils, and thin sheets. It is an essential tool in packaging, food, medical, and materials research industries. By replicating dynamic loading conditions similar to real-world impacts, this tester helps assess a material’s durability and toughness.

When films are used in packaging or product protection, understanding their resistance to sudden forces is critical. This is where the film pendulum impact tester plays a vital role—it simulates high-speed puncture and measures the energy required to rupture the material, offering reliable data for performance evaluation.

ASTM D3420 for Film Pendulum Impact Resistance

O Norma ASTM D3420 test method is the internationally recognized standard for determining the pendulum impact resistance of plastic films. It provides detailed instructions to ensure accurate, repeatable, and comparable results across different testing environments.

This method involves striking a clamped film specimen with a pendulum head at a known velocity and energy level. The energy absorbed by the specimen, leading to rupture or puncture, is calculated from the pendulum’s motion. The test uses two main procedures:

- Procedure A: Uses a 25.4 mm diameter impact head and a 60 mm aperture.

- Procedure B: Uses a 19.0 mm diameter head and an 89 mm aperture (also known as the Spencer test).

Each method suits different material types and testing setups. However, results from Procedure A and B are not interchangeable, as their sample sizes and head diameters yield different impact dynamics.

Working Principle of the Film Pendulum Impact Tester

During the ASTM D3420 test:

- A flat, defect-free specimen (typically 100 mm × 100 mm or Ø100 mm) is clamped between two plates with a circular aperture.

- The pendulum is released from a latched position, swinging with a maximum velocity of ~74 m/min and energy up to 5 J (50 cm·kgf).

- O hemispherical head strikes the center of the film, causing rupture.

- The loss of kinetic energy from the pendulum is measured and translated into impact energy (J) using standard formulas:

-

- For Procedure A:

E = (Scale Reading in cm·kgf) / 10.2 - For Procedure B:

E = (R / 100) × C,

where R is the scale reading and C is the device’s capacity (e.g., 0.17 J to 2.7 J).

- For Procedure A:

Unlike some methods, no correction is made for the tiny fragments punctured, since their mass is negligible.

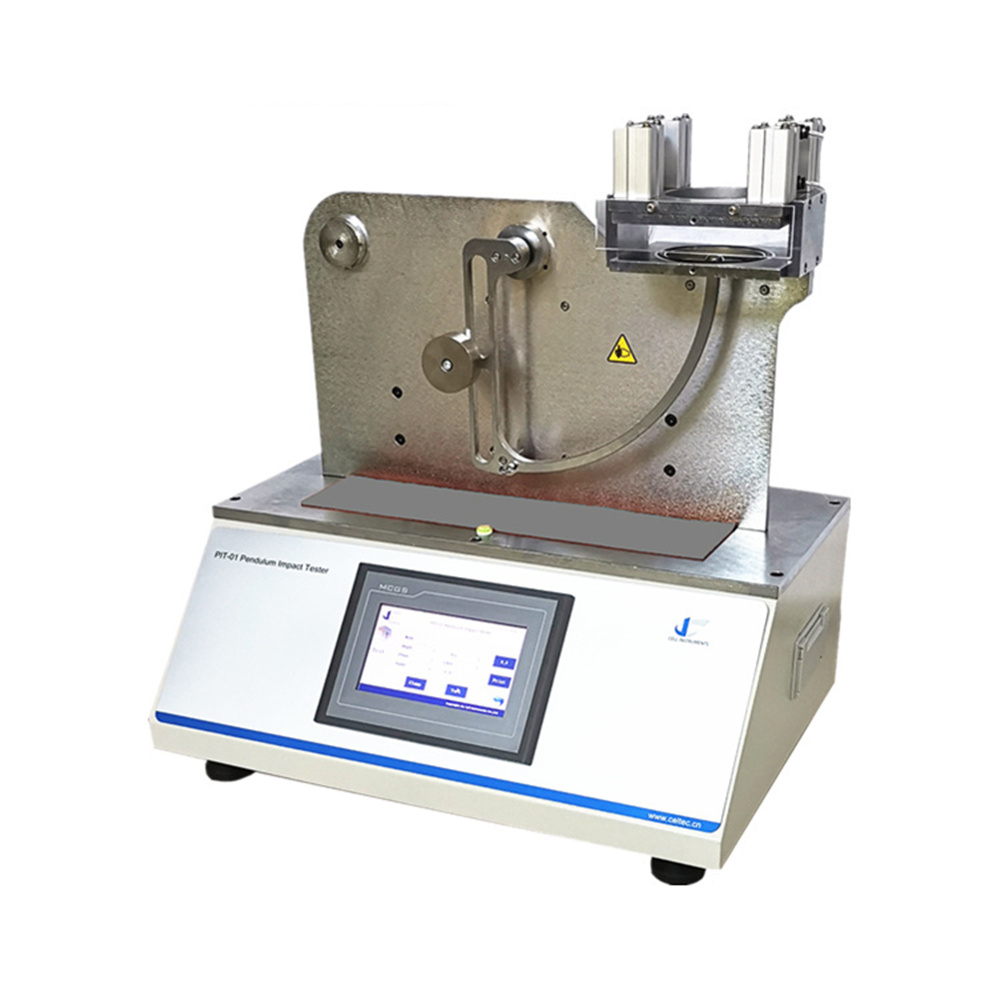

Advanced Features of the PIT-01 Film Pendulum Impact Tester

Manufactured by Cell Instruments Co., Ltd., o PIT-01 film pendulum impact tester is built for full ASTM D3420 compliance, offering accuracy, automation, e user convenience:

- PLC & Touchscreen HMI: Allows simple test configuration and real-time monitoring.

- Pneumatic O-Ring Clamping: Ensures secure, slip-free clamping for consistent data.

- Liberação automática do pêndulo: Enhances precision and safety.

- Data Auto-Processing & Printing: Captures, calculates, and prints results instantly, minimizing human error.

- Multiple Impact Head Sizes: Comes with Φ25.4 mm, Φ19 mm, and Φ12.7 mm heads for test flexibility.

Parâmetro principal

| Energia de Impacto | 1 J, 2 J, 3 J |

| Resolução | 0,001 J |

| Tamanho da cabeça de impacto | Ф25,4, Ф19, Ф12,7 mm |

| Grampo de amostra | Grampo pneumático |

| Diâmetro da braçadeira | Ф89 mm, Ф60 mm |

| Fornecimento de gás | Tubo de PU 0,6 MPa Φ6 mm |

| Tamanho da amostra | 100*100 mm ou Ф100 mm |

| Fonte de energia | CA 110~220V 50Hz |

With its high sensitivity (0.001 J resolution) e wide energy range (1 J to 3 J), the PIT-01 is ideal for both quality control e R&D applications.

Test Procedure Highlights According to ASTM D3420

- Preparação de Amostras: Use flat, uniform films free of defects. At least five specimens are required.

- Thickness Measurement: Measure thickness to the nearest 0.00125 mm.

- Mounting & Impact: Clamp the sample in the holder, raise and latch the pendulum, and release it to impact the sample.

- Registro de dados: Capture the scale reading. If the pendulum doesn’t fully puncture the film, increase energy or reduce film thickness.

- Repeatability: If slippage is observed, retest using a new sample and ensure clamps are properly tightened.

Aplicações em todos os setores

O film pendulum impact tester finds extensive application in:

- Flexible Packaging: Ensures films can withstand transport and handling.

- Medical Packaging: Validates puncture resistance in sterile packaging.

- Food & Beverage Films: Confirms integrity against drops and shocks.

- Construction Materials: Tests barrier films for building insulation and protection.

- Pesquisa e Desenvolvimento: Supports new material formulation and performance benchmarking.

Why Choose PIT-01 from Cell Instruments?

Instrumentos de Célula POÇO-01 stands out due to its precision-engineered components, compliance with ASTM D3420, e intuitive operation. Whether for regulatory validation or production quality control, it ensures:

- Reliable, standardized results

- Reduced human error via automation

- Versatility across film materials

- Compliance with global quality expectations

O film pendulum impact tester is a critical tool for evaluating material toughness under dynamic stress. Adhering to the Norma ASTM D3420 standard, it accurately simulates real-world conditions to ensure films and flexible packaging meet rigorous quality requirements. With the PIT-01 from Cell Instruments, laboratories gain an efficient, precise, and compliant solution for impact resistance testing.

Perguntas frequentes

1. What is the main purpose of ASTM D3420?

ASTM D3420 provides a standardized method for measuring the impact resistance of plastic films using a pendulum device.

2. What are the differences between Procedure A and B?

Procedure A uses a 60 mm aperture and 25.4 mm impact head; Procedure B (Spencer) uses an 89 mm aperture and 19 mm head. They serve different specimen types and aren’t interchangeable.

3. How is the impact energy calculated in this test?

Impact energy is calculated based on scale readings and pendulum capacity using formulas specified in ASTM D3420.

4. What materials can be tested using the PIT-01?

Plastic films, laminated foils, coated paper, and other thin flexible materials used in packaging and protective applications.

5. How does pneumatic clamping improve accuracy?

It minimizes sample slippage, ensuring consistent positioning and reliable test results.

Modelos semelhantes e comparações

- Testador de impacto de dardo em queda (FDT-01)

O Testador de impacto de dardo em queda (FDT-01) é outro dispositivo de teste de impacto amplamente usado que usa um dardo em queda para medir a resistência ao impacto do material. Ao contrário do método do pêndulo, o testador de dardo em queda é projetado para avaliar materiais que são propensos a perfurações sob impacto. - Testador de impacto de bola em queda (FBT-01)

O Testador de impacto de bola em queda (FBT-01) testa materiais deixando cair uma bola de aço sobre o espécime de uma altura definida. Este método é frequentemente usado para testar materiais com espessura ou dureza maiores. - Testadores de impacto Charpy e Izod

O Testador de impacto Charpy e Izod são usados para medir a tenacidade ao impacto de materiais, particularmente metais e plásticos. Esses métodos usam uma abordagem diferente, com um espécime entalhado submetido a um martelo oscilante, mas são frequentemente comparados com testes de impacto de pêndulo para certas aplicações.