Why Ampoule FractureStrength Testing Is Important for Safe Pharmaceutical Packaging

In the pharmaceutical industry, the reliability of packaging is as crucial as the medication itself. Among the most critical packaging components are glass ampoules, widely used for injectables. Understanding why ampoule strength testing is important is essential for ensuring drug safety, regulatory compliance, and operational efficiency. This article explores the significance of strength testing, the testing process as defined by Norma ISO 9187, and how Cell Instruments’ Testador de quebra de ampola BST-01 supports quality assurance.

The Role of Ampoule Fracture Strength in Medical Safety

Ampoules are designed to store sterile medicinal solutions and protect them from contamination and degradation. Any compromise in their structural integrity can pose serious risks, including glass breakage during handling, contamination, or even injury to healthcare professionals.

Therefore, testing the breaking force of ampoules is not just a quality control step—it’s a regulatory and safety requirement. ISO 9187-1:2010 specifically outlines detailed procedures and acceptance criteria for this purpose. Without proper testing, manufacturers risk product recalls, non-compliance, and harm to patients.

Ensuring Compliance with ISO 9187: Breaking Force Requirements

De acordo com ISO 9187-1, ampoules must undergo breaking force tests to ensure a clean and consistent break at the designated point. This standard requires:

- Hydrolytic resistance in compliance with ISO 4802-1 and ISO 4802-2.

- Proper annealing quality, ensuring residual stress is below specified limits.

- UM predetermined breaking point, such as a ceramic ring, to direct fracture.

- Testing performed at controlled temperature (20 ± 5°C) using a tensile testing machine with a test speed of 10 mm/min.

These tests verify that ampoules can be opened easily and safely, minimizing the chance of fragmentation or excessive force during administration.

Importance of the Ampoule Fracture Tester in Quality Assurance

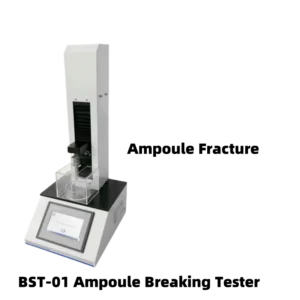

To conduct reliable testing, an ampoule fracture tester is essential. It ensures precise application of force and accurate measurement of break strength. The Testador de quebra de ampola BST-01 de Instrumentos de Célula is a robust solution tailored for this purpose. Key features include:

- Compliance with ISO 9187 test speed and force measurement requirements.

- High-precision load cell technology for accurate and repeatable results.

- User-friendly operation interface, ideal for lab and production environments.

- Opcional visual data recording e test curve outputs for traceable reporting.

O BST-01 ampoule fracture tester provides manufacturers with confidence in both product integrity and compliance documentation. It’s suitable for both R&D and routine batch quality checks.

How Ampoule Fracture Strength Testing Prevents Risk and Enhances Efficiency

Failing to test ampoule strength introduces a cascade of potential failures:

- Breakage during transport leads to waste and contamination.

- Resistance during opening could cause injuries or dosage inaccuracies.

- Glass shards resulting from improper breaks may enter the solution.

Routine strength testing ensures:

- Safe handling by clinicians

- Consistent opening force across production batches

- Lower product rejection rates

- Regulatory compliance and smoother audits

Ao usar um standardized ampoule fracture tester, manufacturers can easily implement statistical quality control and adjust manufacturing parameters based on feedback from test results.

Real-World Application: How to Conduct a Strength Test

Using the BST-01, operators follow these basic steps:

- Condition ampoules to the appropriate test temperature.

- Position the ampoule between test fixtures at a 90° angle.

- Iniciar o teste, allowing the instrument to apply force gradually.

- Record the force at which the ampoule fractures.

- Evaluate results against Norma ISO 9187 specifications (Table 2 values).

The system provides data traceability, which is particularly important when submitting documentation to regulatory bodies or supporting customer audits.

Conclusion: A Critical Step in Sterile Packaging Validation

In summary, why ampoule strength testing is important becomes evident when considering its role in patient safety, operational excellence, and regulatory compliance. A precise and repeatable test process ensures clean ampoule breaks, protects product sterility, and prevents injuries.

Instrumentos de Célula Testador de quebra de ampola BST-01 provides a reliable, ISO-compliant solution to implement these critical tests in any pharmaceutical QA environment. Investing in proper testing infrastructure ultimately reduces risk and builds trust in your brand.