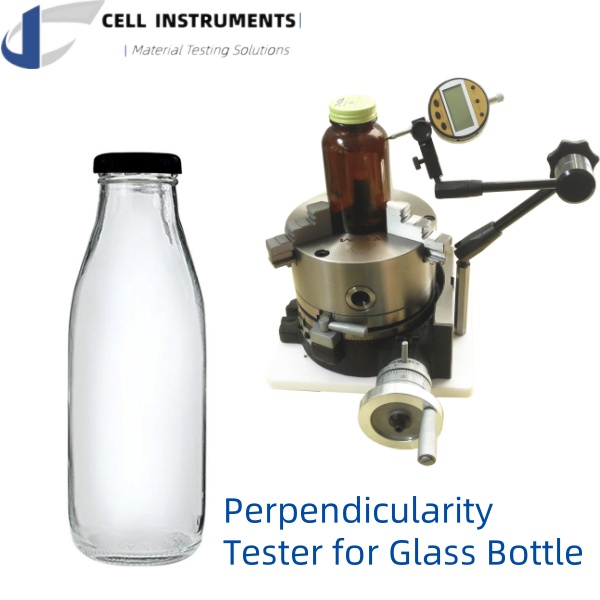

Ensuring the perpendicularity of glass bottles is crucial in maintaining the quality and integrity of various products. In this article, we’ll delve into the significance of glass bottle perpendicularity tests, explore the role of the perpendicularity tester, and recommend the Cell Instruments PER-01 Testador de perpendicularidade de garrafas for precise measurements.

The Role of Glass Bottle Perpendicularity Tests

What is a Glass Bottle Perpendicularity Test?

A glass bottle perpendicularity test measures the alignment of a bottle’s vertical axis with its true perpendicular position. This test is essential for ensuring that bottles are stable, secure, and free from defects that could compromise their quality or safety.

Why is Glass Bottle Perpendicularity Important?

The perpendicularity of glass bottles impacts various aspects of product quality and safety:

- Stability and Integrity: Bottles with incorrect perpendicularity are more prone to tipping over, leading to potential spills and product loss.

- Packaging Efficiency: Properly aligned bottles are easier to pack and transport, reducing the risk of damage during shipping.

- Segurança do Consumidor: Ensuring perpendicularity helps prevent leaks and contamination, which is particularly important for food, beverage, and pharmaceutical products.

Perpendicularity Tester: A Critical Tool in Quality Control

What is a Perpendicularity Tester?

A perpendicularity tester is a specialized instrument designed to measure the deviation of a bottle’s vertical axis from its true perpendicular position. It ensures that bottles meet the required specifications for quality and safety.

Key Features of a Perpendicularity Tester

- Ajuste conveniente da sonda: Allows for easy and precise alignment with the bottle, ensuring consistent and accurate measurements.

- Precisão de leitura excepcional: Provides highly accurate measurements, reducing the likelihood of errors and ensuring compliance with industry standards.

- Rotação de amostra consistente: Ensures uniform testing by measuring the bottle at various points.

- Adesão às especificações da amostra: Ensures that all measurements conform to industry standards, such as ISO 9008.

- Optional Data Export: Facilitates easy data analysis and reporting by allowing users to export test results to PC Excel.

ISO 9008 and Quality Control

ISO 9008 is an international standard that specifies requirements for quality management systems, particularly focusing on the packaging and container industries. Compliance with ISO 9008 ensures that packaging materials and containers meet specific quality and safety standards. The Bottle Perpendicularity Tester from Cell Instruments is designed to adhere to these standards, ensuring that your products meet the highest quality requirements.

Applications of Glass Bottle Perpendicularity Tests

- Indústria de embalagens: Ensures uniformity in packaging, reducing the risk of damage during handling and shipping.

- Indústria de alimentos e bebidas: Maintains product integrity and appearance, preventing leaks and spills.

- Indústria Farmacêutica: Ensures the integrity of medicinal products by maintaining precise bottle perpendicularity.

- Agências de Inspeção de Qualidade: Provides accurate measurements for certifying product compliance with industry standards.

Cell Instruments PER-01 Bottle Perpendicularity Tester

At Cell Instruments, we specialize in providing high-quality materials testing instruments. Our PER-01 Bottle Perpendicularity Tester is designed to ensure the precise perpendicularity of bottles, crucial for maintaining the integrity and quality of bottled products. This instrument is essential for industries such as packaging, food and beverages, pharmaceuticals, and quality inspection agencies.

Key Features of the PER-01

- Highly Adjustable Probe: Ensures easy and precise alignment with the bottle.

- Exceptional Precision: Provides highly accurate measurements of bottle perpendicularity.

- Rotação de amostra consistente: Ensures comprehensive assessment by measuring the bottle at various points.

- Conformidade com a ISO 9008: Adheres strictly to sample specifications and industry standards.

- Optional Data Export: Allows for enhanced data management and reporting.

Benefits of Glass Bottle Perpendicularity Tests

Garantia de qualidade

Ensuring the precise perpendicularity of bottles enhances product quality and consumer safety. This is crucial for maintaining brand reputation and customer satisfaction.

Eficiência de custos

Medições precisas de perpendicularidade reduzem o desperdício e melhoram a eficiência da produção. Ao identificar e corrigir desvios precocemente, o testador ajuda a minimizar os custos de material e o tempo de inatividade da produção.

Conformidade

Meeting industry standards and regulations is essential for business success. The Bottle Perpendicularity Tester ensures that your products comply with ISO 9008 and other relevant standards, reducing the risk of non-compliance issues.

Perguntas frequentes

1. What is bottle perpendicularity? Bottle perpendicularity refers to the alignment of a bottle’s vertical axis with its true perpendicular position. It is essential for ensuring that bottles are stable and secure.

2. How does the Bottle Perpendicularity Tester work? The tester measures the deviation of a bottle’s vertical axis from its true perpendicular position using a precise probe and a rotating mechanism for comprehensive assessment.

3. Why is bottle perpendicularity important? Garantir a perpendicularidade das garrafas é crucial para manter a qualidade do produto, evitar vazamentos e derramamentos e garantir embalagem e transporte eficientes.

4. O testador pode ser personalizado para necessidades específicas? Sim, o testador de perpendicularidade de garrafas pode ser personalizado para atender a requisitos de teste específicos, garantindo que ele forneça as medições exatas necessárias para seus produtos.

5. What industries benefit from using the Bottle Perpendicularity Tester? Indústrias como embalagens, alimentos e bebidas, farmacêuticas e agências de inspeção de qualidade se beneficiam do uso do testador para garantir a qualidade do produto e a conformidade com os padrões da indústria.

Produtos relacionados

Máquina de teste de perpendicularidade de garrafas

Artigo relacionado

Testador de perpendicularidade de garrafas

Teste de perpendicularidade da garrafa