Introduction: Understanding the Role of a Stiffness Tester

A stiffness tester plays a crucial role in the quality control of paper, paperboard, and similar sheet materials. This instrument measures the bending resistance of a sample, providing insight into the paper’s rigidity, handling performance, and suitability for end-use applications. Accurate stiffness evaluation is essential across packaging, printing, and manufacturing industries.

A stiffness tester plays a crucial role in the quality control of paper, paperboard, and similar sheet materials. This instrument measures the bending resistance of a sample, providing insight into the paper’s rigidity, handling performance, and suitability for end-use applications. Accurate stiffness evaluation is essential across packaging, printing, and manufacturing industries.

In this article, we’ll explore how to perform standardized testing using a stiffness tester in accordance with ISO 2493-1, and how it connects with the tensile strength test for paper, enabling manufacturers to ensure consistency and quality.

Why Bending Stiffness Matters in Paper Products

Bending stiffness is directly related to product performance. In folding cartons, brochures, or packaging liners, stiffness affects machinability, user experience, and protection ability. When paper is too soft or too rigid, it may fail to meet functional requirements.

A stiffness tester quantifies this property by applying a defined force to bend a paper sample through a specific angle, then records the resistance. This process allows manufacturers to make informed decisions about raw materials, production processes, and finished goods.

Principles of ISO 2493-1 Testing Method

ISO 2493-1 specifies a precise method for measuring bending resistance. The stiffness tester performs this evaluation through controlled deflection under standard conditions. Here’s how the method works:

- A sample is clamped vertically at one end.

- A knife edge applies force at a set distance (typically 50 mm or 10 mm).

- The clamp rotates through a bending angle of 15° ± 0.3°.

- The force required to reach this angle is recorded as the bending resistance.

This test provides reliable, repeatable results essential for inter-laboratory comparisons and compliance verification.

Test Preparation: Conditioning and Sampling Guidelines

Before using the stiffness tester, samples must be handled according to ISO recommendations:

- Sampling: Follow ISO 186 to select representative samples.

- Conditioning: Maintain standard temperature and humidity as per ISO 187.

- Specimen Preparation: Cut test pieces to (38.0 ± 0.2) mm in width and at least 80 mm in length for 50 mm bending length.

Avoid defects like folds or creases, and ensure both machine direction and cross direction are tested for a comprehensive evaluation.

Step-by-Step Testing Procedure

Perform the bending test under these conditions:

- Insert the sample in the clamp with precise protrusion length (57 ± 3 mm for 50 mm bending).

- Set the angle on the stiffness tester to 15°.

- Ensure the knife edge contacts the sample without applying prior force.

- Initiate rotation and record the force at the designated angle.

- Discard any results from broken, kinked, or excessively deformed samples.

At least 10 valid readings per direction are required for accurate results.

Result Calculation: Bending Resistance and Index

- Bending Resistance is the mean of all valid force readings, reported in millinewtons (mN).

- If necessary, the bending resistance index can be calculated by normalizing the result to the sample’s grammage using the following formula:

Where:

- BB: measured bending resistance (N)

- gg: grammage (g/m²)

- B1B_1: bending resistance index (N·m⁶/g³)

This index is especially useful for comparing papers with similar grammage.

Connection to Tensile Strength Test for Paper

Although bending stiffness and tensile strength test for paper evaluate different properties, they often complement each other in quality analysis. Tensile strength measures how much force paper can withstand before breaking, while stiffness measures resistance to bending or deformation. Combining both tests ensures that a product has adequate strength and rigidity for its application.

Both tests are commonly used in packaging and printing, where performance during converting and end-use is critical. By integrating results from a stiffness tester and tensile tester, manufacturers can better optimize formulations and processing parameters.

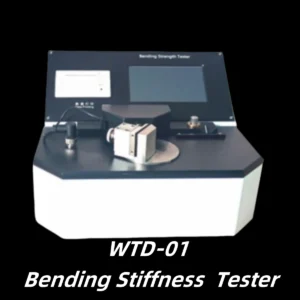

Recommended Equipment: Cell Instruments Tester sztywności

For laboratories and manufacturers looking for reliable and standards-compliant testing, the Cell Instruments Stiffness Tester is a trusted choice. It is engineered to fully meet ISO 2493-1 requirements and offers:

- High precision force measurement

- Adjustable bending length (50 mm or 10 mm)

- Intuitive operation and digital readouts

- Compatibility with various paper grades

Whether you’re assessing folding cartons, corrugated liners, or graphic papers, Cell Instruments provides dependable testing solutions tailored to industry demands.

Conclusion: Achieving Accurate Paper Stiffness Evaluation

Using a stiffness tester in accordance with ISO 2493-1 ensures consistent, accurate assessment of paper bending resistance. When combined with other mechanical tests like the tensile strength test for paper, it forms a robust foundation for material specification, production control, and regulatory compliance.

For comprehensive paper property evaluation, Cell Instruments offers advanced stiffness testing systems that meet global standards and industry needs.