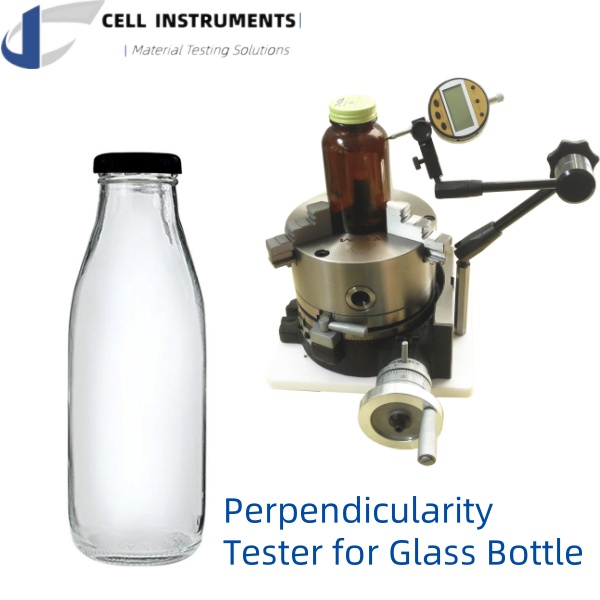

Ensuring the perpendicularity of glass bottles is crucial in maintaining the quality and integrity of various products. In this article, we’ll delve into the significance of glass bottle perpendicularity tests, explore the role of the perpendicularity tester, and recommend the Cell Instruments PER-01 병 수직도 시험기 for precise measurements.

The Role of Glass Bottle Perpendicularity Tests

What is a Glass Bottle Perpendicularity Test?

A glass bottle perpendicularity test measures the alignment of a bottle’s vertical axis with its true perpendicular position. This test is essential for ensuring that bottles are stable, secure, and free from defects that could compromise their quality or safety.

Why is Glass Bottle Perpendicularity Important?

The perpendicularity of glass bottles impacts various aspects of product quality and safety:

- Stability and Integrity: Bottles with incorrect perpendicularity are more prone to tipping over, leading to potential spills and product loss.

- Packaging Efficiency: Properly aligned bottles are easier to pack and transport, reducing the risk of damage during shipping.

- 소비자 안전: Ensuring perpendicularity helps prevent leaks and contamination, which is particularly important for food, beverage, and pharmaceutical products.

Perpendicularity Tester: A Critical Tool in Quality Control

What is a Perpendicularity Tester?

A perpendicularity tester is a specialized instrument designed to measure the deviation of a bottle’s vertical axis from its true perpendicular position. It ensures that bottles meet the required specifications for quality and safety.

Key Features of a Perpendicularity Tester

- 편리한 프로브 조정: Allows for easy and precise alignment with the bottle, ensuring consistent and accurate measurements.

- 뛰어난 판독 정확도: Provides highly accurate measurements, reducing the likelihood of errors and ensuring compliance with industry standards.

- 일관된 샘플 회전: 다양한 지점에서 병을 측정하여 균일한 테스트를 보장합니다.

- 샘플 사양 준수: Ensures that all measurements conform to industry standards, such as ISO 9008.

- Optional Data Export: Facilitates easy data analysis and reporting by allowing users to export test results to PC Excel.

ISO 9008 and Quality Control

ISO 9008 is an international standard that specifies requirements for quality management systems, particularly focusing on the packaging and container industries. Compliance with ISO 9008 ensures that packaging materials and containers meet specific quality and safety standards. The Bottle Perpendicularity Tester from Cell Instruments is designed to adhere to these standards, ensuring that your products meet the highest quality requirements.

Applications of Glass Bottle Perpendicularity Tests

- 포장 산업: Ensures uniformity in packaging, reducing the risk of damage during handling and shipping.

- 식품 및 음료 산업: Maintains product integrity and appearance, preventing leaks and spills.

- 제약 산업: Ensures the integrity of medicinal products by maintaining precise bottle perpendicularity.

- 품질 검사 기관: Provides accurate measurements for certifying product compliance with industry standards.

Cell Instruments PER-01 Bottle Perpendicularity Tester

At Cell Instruments, we specialize in providing high-quality materials testing instruments. Our PER-01 Bottle Perpendicularity Tester is designed to ensure the precise perpendicularity of bottles, crucial for maintaining the integrity and quality of bottled products. This instrument is essential for industries such as packaging, food and beverages, pharmaceuticals, and quality inspection agencies.

Key Features of the PER-01

- Highly Adjustable Probe: 병에 쉽고 정확하게 정렬할 수 있습니다.

- Exceptional Precision: 병의 수직도를 매우 정확하게 측정합니다.

- 일관된 샘플 회전: Ensures comprehensive assessment by measuring the bottle at various points.

- ISO 9008 준수: Adheres strictly to sample specifications and industry standards.

- Optional Data Export: Allows for enhanced data management and reporting.

Benefits of Glass Bottle Perpendicularity Tests

품질 보증

Ensuring the precise perpendicularity of bottles enhances product quality and consumer safety. This is crucial for maintaining brand reputation and customer satisfaction.

비용 효율성

정확한 수직도 측정은 낭비를 줄이고 생산 효율성을 개선합니다. 테스터는 편차를 일찍 식별하고 수정하여 재료 비용과 생산 중단 시간을 최소화하는 데 도움이 됩니다.

규정 준수

Meeting industry standards and regulations is essential for business success. The Bottle Perpendicularity Tester ensures that your products comply with ISO 9008 and other relevant standards, reducing the risk of non-compliance issues.

자주 묻는 질문

1. 병 수직성이란 무엇입니까? 병의 수직성은 병의 수직 축과 실제 수직 위치의 정렬을 말합니다. 병이 안정적이고 안전하게 유지되도록 하는 데 필수적입니다.

2. 병 수직도 테스터는 어떻게 작동합니까? 테스터는 정밀한 탐침과 회전 메커니즘을 사용하여 병의 수직축이 실제 수직 위치에서 벗어난 정도를 측정하여 종합적으로 평가합니다.

3. 병의 수직성이 중요한 이유는 무엇입니까? 병의 수직성을 보장하는 것은 제품 품질을 유지하고, 누출 및 유출을 방지하며, 효율적인 포장 및 운송을 보장하는 데 중요합니다.

4. 테스터를 특정 요구 사항에 맞게 사용자 정의할 수 있습니까? 네, 병 수직도 테스터는 특정 테스트 요건을 충족하도록 사용자 정의가 가능하여 제품에 필요한 정확한 측정값을 제공합니다.

5. 어떤 산업이 병 수직도 테스터를 사용하면 이익을 얻습니까? 포장, 식품 및 음료, 제약, 품질 검사 기관 등의 산업에서는 테스터를 사용하여 제품 품질을 보장하고 업계 표준을 준수하는지 확인하는 데 이점을 얻을 수 있습니다.