Rupture Test for Soft Gelatin Capsules

Ensuring Capsule Strength and Integrity

Soft gelatin capsules have become a crucial delivery system for vitamins, minerals, and pharmaceuticals, owing to their ability to safely enclose liquid fills within a gelatin shell. The effectiveness of these capsules depends significantly on the strength and quality of their gelatin film. The rupture test for soft gelatin capsules is a vital procedure manufacturers and quality control personnel must understand to ensure product reliability and consumer safety.

Importance of the Rupture Test for Soft Gelatin Capsules

Il rupture test for soft gelatin capsules evaluates the capsule wall’s mechanical stability, determining how much force the gelatin shell can withstand before breaking. This test is essential because the integrity of the gelatin capsule shell affects:

-

The protection of active ingredients against environmental factors such as moisture and oxygen.

-

The release profile of the medication or supplement inside the capsule.

-

The capsule’s ability to survive handling, packaging, transportation, and storage without premature bursting.

The test simulates real-world conditions under which capsules might be compressed, squeezed, or impacted, revealing weaknesses that can compromise the product’s quality.

Gelatin Capsule Hardness Test and Bloom Tester: Secondary Key Aspects

One integral aspect of assessing capsule quality is the gelatin capsule hardness test, which measures the mechanical strength and elasticity of the capsule shell. This test often complements the rupture test by providing insights into how the capsule behaves under gradual pressure rather than sudden impact or puncture.

Il bloom tester plays a critical role in this context by measuring the bloom strength of gelatin, which reflects the material’s gel strength. Bloom strength affects both the hardness and flexibility of the capsule film. Higher bloom values correspond to firmer gels, which influence the capsule’s resistance to rupture and deformation.

Methods to Conduct the Rupture Test for Soft Gelatin Capsules

The rupture test primarily involves controlled compression or penetration testing, where a capsule is subjected to force until its shell breaks. Key considerations during the test include:

-

Test Probe Dimensions: Typically a 10 mm diameter or 10 mm² surface area cylindrical probe is used to apply force uniformly across the capsule surface.

-

Misurazione della forza: Measuring the peak force at which the capsule shell ruptures allows for quantitative evaluation of shell strength.

-

Elasticity Assessment: Beyond rupture force, measuring deformation under compression helps identify the capsule film’s elasticity and flexibility.

-

Seal Strength Testing: Testing the force required to break the capsule seal ensures the liquid fill is securely enclosed during manufacturing and distribution.

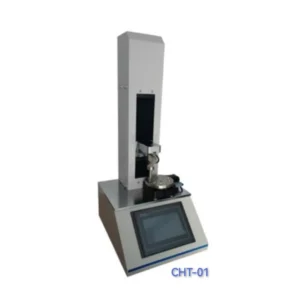

A device designed specifically to meet these testing requirements is the Cell Instruments CHT-01 Soft Gel Capsule Hardness Tester. It provides automated testing with multiple programs, including force control, peak force detection, and distance-based force measurement, enhancing efficiency and consistency in quality control processes.

Why Use the Cell Instruments CHT-01 Soft Gel Capsule Hardness Tester?

Cell Instruments specializes in precise, customizable material testing solutions:

-

The CHT-01 is equipped with a PLC control unit and a user-friendly 7-inch HMI touch screen.

-

Its variable test speed and precision components offer adaptability to different capsule specifications.

-

It simulates realistic stress scenarios like compression and seal rupture, crucial for pharmaceutical packaging and stability.

-

The tester’s automatic returning function and multiple fixture options increase throughput and reduce manual handling errors, streamlining the testing workflow.

By integrating this advanced tester into your quality assurance procedures, you can ensure compliance with pharmaceutical quality standards and enhance patient safety.

Standards and Professional Best Practices

Adhering to international standards such as ASTM and ISO is vital during the rupture test to guarantee reliability and reproducibility of results. Although specific pharmacopeial standards explicitly for gelatin capsule rupture may vary, aligning with mechanical testing norms ensures the integrity of pharmaceutical packaging and supports regulatory submissions.

Industry experts recommend:

-

Performing rupture tests regularly on production batches to detect manufacturing inconsistencies.

-

Combining hardness and bloom strength testing to understand the gelatin film’s comprehensive mechanical profile.

-

Documenting and analyzing trends in capsule strength to inform manufacturing adjustments.

Conclusion: Enhancing Quality Control with Informed Testing

Il rupture test for soft gelatin capsules serves as a critical quality measure ensuring capsules withstand mechanical stresses without damage, thus safeguarding product efficacy. Incorporating the gelatin capsule hardness test and measuring bloom strength further refines the understanding of capsule robustness.

Strumenti a cella offers reliable, customizable solutions like the CHT-01 hardness tester that facilitate accurate and efficient testing. Leveraging such equipment and following best practices will help pharmaceutical manufacturers and quality control professionals maintain high standards, reduce product failures, and improve consumer confidence.